The global CNC (computer numerical control) machine market size is expected to have a CAGR of 9.9%, resulting in the growth level reaching USD 195.59 billion by 2032, from 101.22 billion in 2025 (Fortune Business Insights).

CNC machining has become the most used machining method in the world by automating the long process of manufacturing using the CAD/CAM method. Today, CNC machining influences every industry in the world with its ultramodern approach to production and precision.

In this blog, we’re trying to understand and quantify the impact of CNC machining on international industries and brands. If you’re on a research purpose that takes a deep look into this computerized tooling method, then this blog is for you.

What Makes CNC Machining So Universal?

Whether it’s space research, the coal industry, medicine, or fashion, all of them depend on CNC machining in one way or another. It might be for producing certain products or improving the efficiency of the sector and reducing the cost of operation.

The increasing exclusive nature of the components and customization make CNC machining an integral part of several industries. CNC machining provides the freedom to tailor the service and products with the help of automated manufacturing.

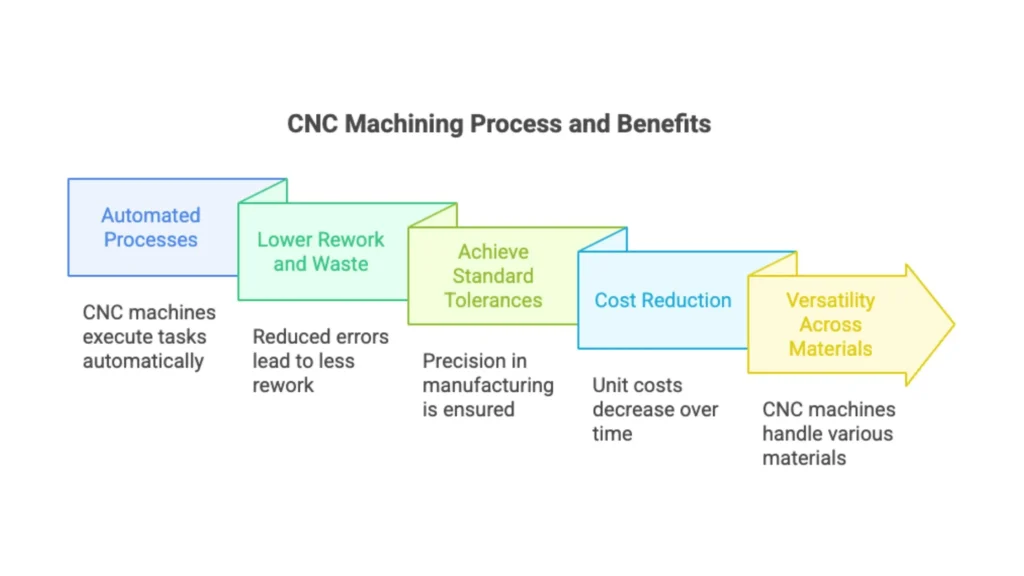

Look at what makes CNC machining universal.

- Reduce error/defect rates by 30%

- Automated processes, lower rework and waste

- Achieve standard tolerances of ±0.13 mm (±0.005 in)

- Cost per unit decreases noticeably over 1-3 years

- Versatility across different materials for general-purpose part dimensions

Curious about how CNC achieves this? Explore our detailed post on how CNC machining works in practice.

Industries Using CNC Machinary

1. Aerospace Industry

Aerodynamic forces, high temperature, and stress in the aerospace industry demand super precision and durability for aircraft and spacecraft components. Here, CNC machining delivers superior-quality parts that are safe from even a microscopic error and meet safety standards.

Key Applications of CNC in Aerospace

| Category | Examples | Purpose/Focus |

| Engine Components | Turbine blades, rotors, compressor parts, casings | Achieve precise tolerances |

| Airframe Structures | Fuselage panels, wing ribs, landing gear (aluminum or titanium) | Lightweight yet strong construction |

| Avionics & Control Systems | Sensor housings, navigation system parts, cockpit control enclosures | Accurate and durable electronic support |

| Fasteners & Connectors | Precision bolts, rivets, mounts | Reliable aircraft assembly |

| Prototyping & R&D | Advanced alloys, composite testing | Validate before large-scale production |

Case Studies

- NASA manufactures heat- and vibration-resistant turbine blades and engine chambers using 5-axis CNC machining.

- Boeing produces their lightweight commercial aircraft components, like aluminum fuselage parts and wing sections, with the help of CNC milling.

- Airbus relies on CNC machining for landing gear assemblies and titanium brackets that reduce aircraft weight while maintaining strength.

2. Automotive Industry

CNC machining services support the automotive sector with mass production and precision engineering. The accuracy it offers makes the automotive industry rely on it for custom prototyping and manufacturing, EV innovations, and detailing.

Key Applications of CNC in Automotive

| Category | Examples | Purpose/Focus |

| Engine & Transmission Parts | Engine blocks, cylinder heads, pistons, crankshafts, gear systems | Micron-level accuracy for performance & reliability |

| Brake & Suspension Systems | Brake callipers, discs, suspension arms | Precision manufacturing for safety & stability |

| Prototyping New Models | Concept cars, EV prototypes | Test designs before mass production |

| Interior & Exterior Components | Dashboard molds, alloy wheel prototypes, custom trims | High-quality finish & design flexibility |

| Aftermarket Customization | Custom engine parts, racing modifications, aesthetic upgrades | Personalized performance & styling |

Case Studies

- Tata Motors (India): CNC machining for EV powertrain parts → lightweight, efficient electric designs.

- Tesla: Battery casings and chassis components → scaled production in Gigafactories.

- BMW & Mercedes-Benz: CNC enables rapid prototyping → faster design cycles for luxury models.

Read about CNC machining in the automotive industry in India to learn more.

3. Medical & Healthcare

In the healthcare sector, CNC machining helps to manufacture surgical instruments to implants that meet FDA/ISO standards. Do you know how CNC benefits the medical industry?

- Uses biocompatible materials like titanium, stainless steel, cobalt-chrome, and PEEK plastics.

- Provides rapid prototyping for new medical devices, reducing R&D time.

- Reaches micron-level tolerances for implants and surgical devices.

- Helps in customizing prosthetics for every patient in need.

Key Applications of CNC in Medical & Healthcare

| Category | Examples | Why It Matters |

| Surgical Tools | Scalpels, forceps, clamps, drill guides | Accurate and reliable tools for surgery |

| Orthopedic Implants | Bone plates, spinal implants, hip & knee parts | Strong, body-friendly parts that fit perfectly |

| Dental Devices | Crowns, bridges, braces, aligners | Comfortable, custom-fit dental solutions |

| Prosthetics | Joints, limb fittings | Lightweight, natural movement support |

| Medical Equipment | MRI housings, ventilator parts, casings | Protects and supports hospital machines |

| Micro-Parts | Endoscope tips, tiny surgical tools | Enables delicate, less invasive treatments |

Case Studies

- Apollo Hospitals in India has been customizing biocompatible titanium hip implants for long-term durability.

- Johnson & Johnson (DePuy Synthes) uses CNC machining to create orthopedic screws and spinal implants with FDA standards.

- Straumann Dental Hospital in Switzerland relies on multiaxis CNC for the fast production of dental implants.

4. Electronics

Manual machining capabilities can never meet the demands of miniaturization, precision, and mass production for electronics manufacturing in smartphones, laptops, circuit boards, etc.

Here, CNC machining guarantees efficient production of micro components, rapid prototyping, and thermal management for metals like aluminum, copper, etc.

They also support custom manufacturing of housing for better durability and design freedom.

Key Applications of CNC in Electronics

| Application | Example Components | Purpose / Benefit |

| Circuit Board Housings | Enclosures for PCBs, semiconductor casings | Protects delicate electronics, maintains structural integrity |

| Smartphone & Laptop Frames | Aluminum unibody frames (e.g., MacBook, iPhone) | Delivers strength, lightweight design, and premium aesthetics |

| Heat Sinks | Copper/aluminum cooling components | Enhances heat dissipation, prolongs device life |

| Connector Pins & Micro Components | Pins, sockets, precision connectors | Provide accurate alignment and reliable electrical performance |

| Custom Prototyping | Prototype enclosures, test models | Speeds up R&D cycles, shortens time-to-market |

| Wearables & IoT Devices | Casings for smartwatches, AR glasses, IoT sensors | Offers a sleek, ergonomic, and durable designs |

Real-World Case Studies

- Apple: The 0.4 mm flatness of the iPad Pro aluminum body is attained by CNC machining for strength and a premium finish.

- Venttup Ventures: Helped A-Bond Strands save 17% of costs with better leads when providing 33 kV shaft, quench rod pin, switch rod & head, and pipe axis.

- Intel: Works with special CNC-made heat sinks to cool powerful chips that sometimes use more than 1000 watts of power or a concentrated power of 200 watts per square meter.

- Samsung: Employs CNC machining to design custom molds for smartphone camera housings with ultra-fine tolerances.

5. Defense & Military

Security of every nation is strengthened by defense and defense-related equipment. So you need tools and machines that support you at critical times with 100% reliability, durability, and precision.

- Operate under extreme conditions: Components must withstand intense heat, high pressure, and battlefield-level impacts without failure.

- Micron-level accuracy: A misaligned chamber or guidance housing, even by a few microns (smaller than a red blood cell), could compromise a weapon system.

- Consistency in mass production: Defense projects need thousands of identical, mission-critical parts.

- Advanced materials & designs: CNC machines can cut through defense-grade alloys such as titanium, Inconel, and hardened steel, while shaping complex geometries that manual methods cannot achieve.

Key Applications of CNC in Defense & Firearms

| Category | Components | Purpose / Importance |

| Firearms & Weapon Systems | Barrels, triggers, chambers, mounts | Achieve absolute accuracy and reliability under high stress |

| Aerospace & Defense Aircraft | Jet turbine parts, drone frames, helicopter rotor hubs | Lightweight, strong, and heat-resistant parts for combat aircraft |

| Armored Vehicles | Engine housings, suspension arms, ballistic panels | Durability and protection in battlefield conditions |

| Naval Applications | Propeller shafts, torpedo casings, submarine systems | Precision machining provides high-performance in extreme underwater environments |

| Communication Devices | Rugged enclosures for radios, radar systems, satellite units | Withstand shock, vibration, and harsh weather |

| Missile Systems | Guidance housings, propulsion system parts | Micron-level tolerances needed for targeting and flight stability |

Case Studies

- Venttup Ventures: Applied CNC machining to manufacture copper rotors and motor shafts for defense applications with 100% fitment support.

6. Oil & Gas

The oil and gas sector operates in deep-sea rigs battling 20,000 psi of pressure to refineries where temperatures exceed 1000°F. In these conditions, even a minor crack in a valve or flange can cost millions in downtime and pose serious safety risks.

Here, CNC machining is vital because it provides:

- Every part is cut perfectly by avoiding gaps or weak spots.

- Handles tough alloys like Inconel, steel, and titanium for corrosion and heat resilience.

- Gives operators the freedom to design components that match their specific drilling or refinery needs.

- Produces large batches with the same accuracy every time, so there’s no variation in quality.

Key Applications of CNC in Oil & Gas

| Category | Examples | Why It Matters |

| Drilling Equipment | Drill bits, drill collars, mud motor parts, rotary steerable tools | Handles constant wear, high torque, and deep drilling pressures |

| Valves & Pumps | High-pressure valves, compressor housings, pump impellers | Controls the flow of oil, gas, and drilling fluids under extreme conditions |

| Pipeline Components | Flanges, connectors, fittings | Withstands high pressure and promises safe, leak-proof transport |

| Refinery Parts | Seals, turbine housings, heat exchanger elements | Supports continuous operation in high heat and corrosive environments |

| Subsea Equipment | Casings, housings for underwater use | Built with anti-corrosion protection for deep-sea oil & gas exploration |

7. Marine & Shipbuilding

Ships, submarines, and offshore platforms must endure saltwater corrosion, crushing pressure, and decades of wear. That is why CNC machining becomes essential for measurable performance improvements at sea:

- Works with marine-grade materials like stainless steel, bronze, brass, and titanium.

- Accurate designs help save around 1.4% fuel on a 25-meter vessel.

- The cupped shape reduced fuel consumption by 5–6% on long routes.

- Allows for repairs and replacements even decades after the original build.

CNC Applications in Marine & Shipbuilding

| Category | Examples | Why It Matters |

| Propellers & Shafts | Large propellers, drive shafts | Multi-axis CNC offers a smooth performance and fuel efficiency |

| Engines & Transmission | Housings, pistons, fuel injection parts | Precision machining improves power, durability, and safety |

| Hull & Structural Parts | Panels, brackets, joints | Accurate fit for strong, seamless ship structures |

| Navigation & Control | Sonar, radar, GPS housings | Reliable protection for sensitive navigation systems |

| Submarine & Offshore Equipment | Pressure casings, valves, subsea connectors | Withstands high pressure and corrosion in deep-sea environments |

| Luxury Yachts | Interiors, custom fittings, decorative parts | Enables detailed finishing for comfort and aesthetics |

Case Studies

- Hyundai Heavy Industries: Their massive 11-meter, 114-ton ship propellers and large marine engines depend on multi-axis CNC machining for shaping and balancing.

- Mazagon Dock Shipbuilders: The Scorpene-class submarines use CNC-machined components like hull sections, propeller shafts, and weapon mounts.

- Rolls-Royce Marine: Their Promas propulsion system and high-performance propellers rely heavily on 5-axis CNC machining to achieve the required hydrodynamic efficiency and surface finish.

8. Jewelry & Luxury Goods

The global jewelry cutting machines market is forecasted to reach $5013.97 million by 2033, from $2947.07 million (2021), with a CAGR of 4.528%, influenced by the modern methods of jewelry manufacturing.

The exclusivity of jewelry and luxury goods demands precision and complex design that showcases the craftsmanship that steals the spotlight. Many high-end brands rely on CNC machining, especially when it comes to achieving submicron tolerances (0.1-1 micron).

- Helps to reach a surface finish greater than Ra0.1 μm in lightweight materials

- Reduces wastage and enables effective use of valuable materials like gold and silver.

- Create intricate designs using CNC 5-axis linkage technology.

Key Applications of CNC in Jewelry & Luxury

| Category | Examples | Why It Matters |

| Engraving & Fine Cuts | Rings, pendants, bracelets | Creates detailed patterns and designs with perfect precision |

| Custom Watchmaking | Gears, dials, bezels | For accuracy and premium finishing in luxury timepieces |

| Diamond & Gem Setting | Stone prongs, mountings | Guarantees a secure, exact placement of precious stones |

| Personalized Jewelry | Names, logos, patterns | Delivers unique, custom-made designs for clients |

| Prototyping Collections | Trial designs before mass production | Allows designers to test new ideas quickly and cost-effectively |

| Luxury Accessories | Eyewear frames, pen casings, cufflinks | Provides sleek finishes and durability for high-end goods |

Case Studies

- Cartier (France): Their watches are produced using CNC milling and drilling, and each component is checked over 100 times.

- Rolex (Switzerland): The Rolex watches demand precision within 4 microns, and they reach the correct accuracy after over 50 machining operations.

- Tanishq (India): Tanishq relies heavily on CNC CAD/CAM software and tooling methods to customize and innovate its designs.

9. Furniture & Woodworking

The furniture sector acquired 48% of the global rear-loading CNC panel in 2023, showing the reliance of the industry on CNC. Several studies provide proof of the benefits of CNC machining in furniture manufacturing and woodworking. For example, in Australia, this modern technique has reduced the raw material demand by maximizing its usage and minimizing the sanding.

Take a look at how CNC improves the efficiency of the furniture woodworking sector.

- Support mass customization and materials utilization compared to traditional machining.

- Providing flexibility in materials (hardwood, plywood, MDF, laminates, plastics, composites).

- Speed up product development with one-off prototyping in 5-7 days

- Reduce labor costs up to 22% in the retail business

Key Applications of CNC in Furniture & Woodworking

| Category | Examples | Why It Matters |

| Custom Furniture Design | Chairs, tables, cabinets, modular furniture | Enables creative shapes and personalized designs |

| Wood Carvings & Engravings | Luxury furniture detailing, temple woodwork, heritage reproductions | Delivers fine detailing that’s hard to achieve by hand |

| Panel Cutting & Cabinetry | Kitchen units, wardrobes, office furniture panels | Optimizes material use and ensures precise, repeatable cuts |

| Interior Décor | Decorative wall panels, 3D wood art, modular partitions | Adds unique style elements to homes and commercial spaces |

| Prototyping & Model Making | Ergonomic mockups, scale models | Let designers test ideas before mass production |

| Joinery & Fittings | Mortises, tenons, precision joints | Creates stronger, longer-lasting builds with perfect alignment |

Case Studies

- IKEA (Global): IKEA produces furniture in large batches and stays within the eco-friendly goals with the help of modern manufacturing methods like CNC machining.

- Godrej Interio (India): Strong and automated cutting of CNC enables Godrej to work with hard metals like Inconel, titanium, and steel.

- Small-Scale Artisans: Local woodworkers follow a hybrid method by combining CNC and manual machining. This helps them to create complex designs with tight accuracy over components.

10. Construction & Heavy Machinery

Every part used in heavy machinery manufacturing, like excavators and cranes, from hydraulic pumps to bulldozers, must endure intense loads, vibrations, and harsh outdoor environments. CNC machining guarantees:

- Machines heavy machinery components within ±0.13 and ±0.01 mm

- Reduces prototyping costs by 61% and design cycle time by 32%

- Produces parts with engineering-grade materials like PEEK, Delrin, and 6061 aluminum

CNC Applications in Construction & Heavy Machinery

| Category | Examples | Why It Matters |

| Hydraulic Systems | Pump housings, pistons, hydraulic cylinders | Powers cranes, excavators, and other heavy machinery with reliability |

| Structural Components | Brackets, joints, frames | Provides strength and stability to support massive loads |

| Transmission & Powertrain Parts | Gears, shafts, couplings | Smooth power transfer in bulldozers, loaders, and rollers |

| Excavator & Loader Parts | Buckets, arms, wear plates | Built for durability and resistance against heavy wear and tear |

| Infrastructure Equipment | Concrete molds, scaffolding joints, tunnel boring components | Enables precision in large-scale construction projects |

| Mining & Quarry Equipment | Drilling tools, crusher parts | Handles high-impact and abrasive environments for continuous operation |

Case Studies

- Venttup Ventures: Provided pivot foot assembly with 100% quality and surface finish to support individual columns in construction projects of Tvasta.

- The public job listings of Caterpillar show that CNC is central to component production of engine housings and hydraulic parts, since they actively recruit CNC operators.

- Larsen & Toubro (India) uses CNC for large fabrication and precision parts in infrastructure and road-construction machinery.

- A-Bond Strands: Reduced cost (15%) and lead time with the help of Venttup Ventures CNC machining while manufacturing cone gear, cam plate, and trip parts.

- Komatsu (Japan): CNC plays a crucial role in the 24/7 manufacture of powertrain parts and the remanufacturing process of engines for better tolerances and performance.

Go to Compare efficiency in CNC vs conventional machining to understand how both tooling methods differ in their performance.

11. Railways

The cost of railway accidents is the cost of lives and the economy of a country. That is why it is one of the most critical industries in the world that needs safety, reliability, and efficiency. A minor fault or a micron inaccuracy is enough to create serious issues.

Here, CNC helps railways to:

- Meet wheel–axle press fit tolerance (~200–230 µm) to reduce vibration.

- Work with steel alloys of 560 MPa to avoid deformation under stress.

- Produce components with tight tolerances when it comes to repair and replacements.

CNC Applications in Railways

| Category | Examples | Why It Matters |

| Wheels & Axles | Precision-balanced wheels, axles | Reduces wear, vibration, and maintenance costs |

| Brake Systems | Brake discs, callipers, pads | Safe and reliable braking performance |

| Locomotive Engines | Engine housings, pistons, fuel system parts | Improves the durability and efficiency of diesel and electric locomotives |

| Rail Track Components | Joints, couplings, fasteners | Built to handle extreme loads and long-term pressure |

| Bogies & Suspension | Brackets, supports, shock-absorbing parts | Provides stability and smoother rides for passengers |

| High-Speed Trains | Lightweight aluminum parts, aerodynamic fittings | Enables faster speeds with reduced energy consumption |

Case Studies

- Indian Railways: Uses CNC machining in wheel and axle manufacturing plants (e.g., the Rai Bareli coach factory) for better safety and to reduce downtime.

- Venttup Ventures: Supplied 26 MT of 33 kV base frames of various sizes for the BMRCL project of Siemens, meeting specifications and improving lead time.

- Alstom (France): The Mátranovák 2030 development plan (2022) has advanced the CNC plasma cutting machine in their firm, helping them to revamp 770 bogies in one year.

- Siemens Mobility (Germany): Relies on SINUMERIK ONE CNC for locomotive engines and precision couplers in European rail networks.

12. Renewable Energy (Wind, Solar, Hydro)

Manufacturers are machining wind turbine hubs weighing up to 40 tons and up to 6 m in diameter with CNC, achieving finish tolerances of about ±0.01 mm on critical interfaces. This way, companies perfect their bolt alignment, rotor balance, and reliable nacelle fit.

- Uses hard, corrosion-resistant materials like stainless steel, titanium, composites, and carbon fiber.

- It enables large-scale component manufacturing (wind turbine hubs, hydro shafts).

- Supports lightweight designs that maximize efficiency in solar and wind applications.

- Long operational life through repeatable, high-tolerance manufacturing.

Key Applications of CNC in Renewable Energy

| Renewable Energy Source | Key CNC Applications |

| Wind Energy | Turbine hubs & blade molds, precision-machined gearboxes & bearings, nacelle housings for internal mechanisms |

| Solar Energy | CNC-made aluminum panel frames & mounts, machined joints and couplings for solar trackers, housings for inverters & cooling systems |

| Hydropower | Large CNC-machined turbine blades & runners (Francis, Kaplan, Pelton), shafts & casings for durability, seals & valves for leak prevention under high pressure |

Case Studies

- Siemens Gamesa (Spain): Uses 5-axis CNC machining to create giant molds for wind turbine blades and aerodynamic efficiency.

- Venttup Ventures: Supplied the mounting structure for Dexler for their solar projects using CNC. Delivered 100 MT volume on time by minimizing cost from 6-8%.

- Suzlon Energy (India): Their new blade facility at Badnawar produces 400 MW worth of rotor blades annually, with lengths up to 54.8 meters, using CNC machining.

- Hitachi Energy: Manufactured the capacitor tilt trolley with the CNC service provided by Venttup Ventures that helped in achieving a cost reduction (25%) and lead time (30%).

13. Mining Industry

Unplanned downtime caused by equipment failure in the mining industry can cost up to $180,000 in a single event and reach up to $10 billion a year. That is why this industry can’t risk the endurance rate of the tools and equipment. CNC-machined parts help avoid these situations.

Key Applications of CNC in Mining

| Category | Examples | Why It Matters |

| Excavator & Loader Parts | Buckets, arms, joints | Withstand heavy loads and rough use. |

| Drilling Tools & Bits | Drill bits, rotary cutters | Cut through hard rock efficiently. |

| Crusher & Grinding Components | Crusher jaws, liners, mill parts | Resist wear from abrasive materials. |

| Conveyor Systems | Shafts, rollers, housings | Keep material moving without breakdowns. |

| Safety Equipment | Casings, brackets | Protect monitoring devices for worker safety. |

| Underground Equipment | Tunnel boring and loader parts | Enable safe, effective underground mining. |

Case Studies

- Caterpillar (USA): Caterpillar’s supply chain and in-house machining lines rely on advanced CNC machine tools, precision cutting tools, and FMS automation.

- Coal India Limited (India): Relies on CNC machining for crusher components and drilling bits to support large-scale coal extraction.

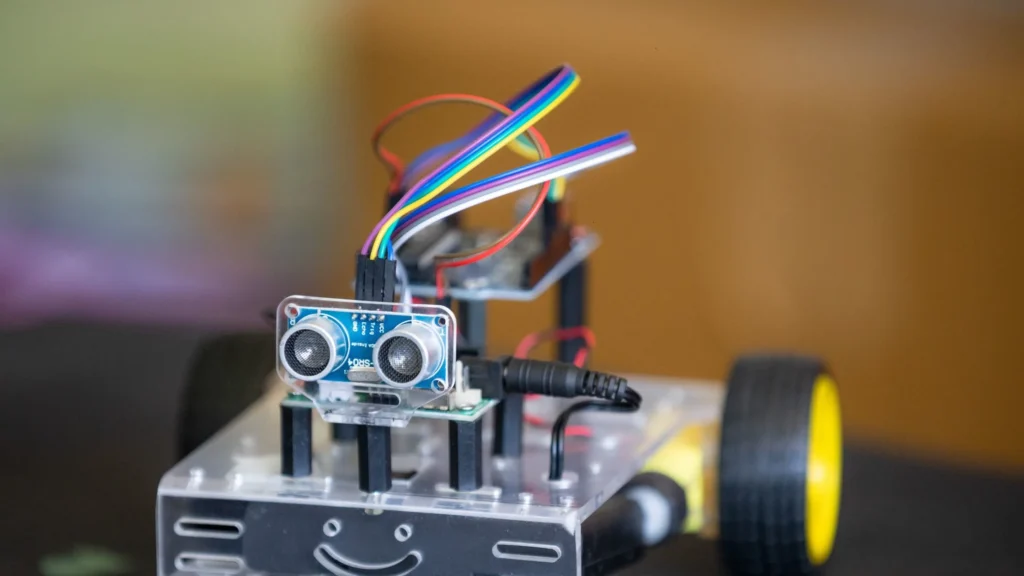

14. Robotics & Automation

The demand for CNC machining is very high in the robotics and automation industry since the sector requires ±0.005-0.01 mm tolerances and parts made with 7075-T6 aluminum, stainless steel, and titanium. Let’s take a look at how CNC machining enables advancements in robotics.

- Create humanoid/hybrid robot components with surface finishes of Ra ≤ 0.2 µm

- Reduce weight by 30% and improve the development cycle by 50% using 5-axis CNC

- Manufacture transmission gears with concentricity under 10 µm and surface finish

- CNC gear machining prevents reduced precision and noise production

Key Applications of CNC in Robotics & Automation

| Component | CNC Machining Role / Benefit |

| Robotic Joints & Arms | Produces high-precision pivot joints and arm components for smooth, repeatable movement. |

| Gears & Transmission Systems | Manufactures small gears and shafts with micron-level tolerances, critical for accuracy in industrial robots. |

| Sensor & Camera Housings | Creates custom enclosures that protect delicate vision systems and sensors while maintaining alignment. |

| End Effectors (Grippers/Tools) | Enables custom-made grippers and tools used in manufacturing, packaging, and medical robotics. |

| Automation Fixtures | Machine frames, mounts, and brackets for reliable use in automated assembly lines. |

| Collaborative Robots (Cobots) | Provides lightweight, durable structures that ensure both safety and precision when working alongside humans. |

Case Studies

- ABB Robotics (Switzerland): Enhances factory automation utilizing CNC for the production of robotic arm components and precision gears

- Fanuc (Japan): Has improved the efficiency and accuracy of robotic systems used in global manufacturing plants, including Kemco, JTEKT, MIP, and Flex-N-Gate.

15. Sports Equipment

Do you know? Almost 2% of the global CNC machining is used for manufacturing durable and high-quality sports equipment (News Market US). This modern machining method has helped them manufacture lightweight KD-1 clubs and bicycle components and reduce air resistance when it comes to driving sports.

- Lathes and milling machines process chainrings with tolerances of ±0.02 mm.

- Offer 8–10% air resistance by manufacturing using carbon fiber frames.

- Increase the longevity of sports equipment with the help of anodizing, hardness HV 500, etc.

- Meets sustainability goals of reduced material wastage and supports recycling.

Key Applications of CNC in Sports Equipment

| Sports Category | CNC Applications | Why It Matters |

| Cycling | Aluminum bike frames, cranksets, and gears are machined with CNC. | Delivers lightweight yet durable components essential for competitive performance. |

| Golf Clubs | Custom-milled club heads and shafts. | Enhances precision, swing balance, and player customization. |

| Tennis & Badminton | Racket frame molds and grip components. | Provides consistent frame quality and ergonomic comfort. |

| Cricket & Baseball | CNC molds for bats and ball manufacturing tools. | Uniformity and durability in high-impact equipment. |

| Helmets & Protective Gear | CNC-machined molds for lightweight, impact-resistant designs. | Improves safety without compromising comfort. |

| Extreme Sports Gear | Snowboards, skateboards, and racing car parts shaped with CNC. | Supports durability and aerodynamic performance in demanding sports. |

Real-World Case Studies

- Salomon (Amer Sports): Reuses 30% recycled materials and achieves ±0.03 mm with 5-axis CNC machining.

- Rossignol (France): Woodcore shaping CNC routing systems helped them manufacture 500,000 ski pairs annually.

- Trek Bicycles: They increase strength by 15% and minimize weight by 10% of weight using their bike’s CNC machining on carbon fiber frames.

16. Textile & Fashion Industry

The fashion industry looks for exclusivity and creativity even when they are highly influenced by sustainability and eco-friendly policies. CNC machining helps this industry to keep up with fast-changing trends while staying on track with eco-consciousness.

Key Applications of CNC in Textile & Fashion

| Fashion Segment | CNC Role | Impact |

| Apparel | Fabric cutting & pattern making with CNC laser cutters and routers. | Consistent sizing, reduced fabric waste, and faster production cycles. |

| Embroidery & Detailing | Dies and molds for embroidery designs. | Achieves fine detailing and repeatable patterns impossible by hand. |

| Footwear | CNC molds for soles, insoles, and sports shoes. | Provides ergonomic comfort and scalable customization for brands. |

| Accessories | Jewelry, belts, buckles, and watch parts. | Enables luxury-grade precision and durability in fashion accessories. |

| Textile Machinery | Machined rollers, guides, and casings. | Improves the efficiency and reliability of textile production lines. |

| High-End Fashion | CNC prototyping for limited edition collections. | Empowers designers with flexibility for unique, small-batch runs. |

Real-World Case Studies

Nike (USA): Programmable CNC knitting machines for Flyknit minimized cutting waste by up to 60%, and automated high-resolution cameras detect fiber irregularities.

17. Agriculture & Farming Machinery

Heavy-duty machinery like tractors, harvesters, seeders, and irrigation systems runs for over 1000 hours before the overhaul. And the agricultural hydraulic circuits operate at 1500–4600 psi.

The data above show critical requirements of the industry. Manual machining always fails to provide this accuracy and performance efficiency due to errors.

CNC machining helps the agriculture sector by:

- Provides parts with high-strength steels AISI 4140 with 415 MPa and 6061-T6 aluminum with 276 MPa.

- Produce prototype or replacement parts in 24–72 hours.

- Delivers wear-resistant, high-strength parts for farming equipment.

- Mass production consistency for thousands of identical parts used in large farms.

Key Applications of CNC in Agriculture

| Area | CNC Examples | Why It Matters |

| Tractors | Transmission gears, engine housings, axles | Keeps tractors reliable and reduces breakdowns. |

| Harvesting Equipment | Blades, cutters, threshing parts | Improves crop yield and speeds up harvesting. |

| Irrigation | Pump parts, valves, connectors | Extends system life and prevents leaks. |

| Soil Tools | Plough blades, seed drill nozzles, cultivator parts | Precise planting and efficient tilling. |

| Smart Farming Devices | Housings for GPS, sensors, autonomous modules | Protects electronics from dust, mud, and vibration. |

| Special Attachments & Robotics | Custom add-ons for tractors, automated arms | Adapt equipment for different crops and tasks. |

Real-World Case Studies

- John Deere (USA): Employs CNC for hydraulic, transmission, and 9RX 830 (2025), backed by $2.5B investment, $52.58B sales (2024), and 60%+ AI by 2025.

- Mahindra & Mahindra (India): Grows with CNC engine, harvesting tool production, and leads the Indian tractor market by holding 13% of it with durable, efficient products.

18. Aviation (Commercial Aircraft)

The safety and fuel efficiency requirements are easily achieved since the arrival of CNC machining. This modern manufacturing has helped commercial aircraft last for tens of thousands of flight cycles and meet strict standards like AS9100D.

CNC machining is essential because it:

- Works with titanium alloys like Ti-6Al-4V with 1000 MPa tensile strength

- Offer fatigue resistance needed for fan blades, landing gear, and engine mounts

- Cut component weight by 25–40% to reduce fuel use

- Guarantees micron-level accuracy with CMM inspections for certified quality

- Help to create parts with 1.5 mm thick walls.

Key Applications of CNC in Commercial Aviation

| Application | CNC-Machined Parts | Why CNC Is Used |

| Landing Gear | Struts, brackets, actuator housings | Strong, precise parts that handle heavy loads |

| Engine Components | Fan blades, compressor discs, casings | Accurate, durable parts for high-speed engines |

| Cabin & Interior | Seat frames, tray tables, custom fittings | Lightweight and custom-made for comfort and safety |

| Structural Components | Fuselage panels, wing ribs, bulkheads | Strong, precise parts that reduce weight |

| Avionics & Control Housings | Enclosures for navigation and flight systems | Protects sensitive electronics reliably |

| Maintenance & Repairs | Replacement parts | Quick on-demand parts to reduce aircraft downtime |

Real-World Case Studies

- Boeing (located in the USA): Applies CNC to the fuselage, wings, and landing gear and produces 38 aircraft per month, including 5 Dreamliners.

- Airbus (located in France): 5-axis CNC enables lighter, more durable, precise, modular designs and relatively maintenance-free, easy-to-service fabrications.

- HAL (located in India): Uses CNC for the construction and maintenance of combat aircraft and helicopters.

19. Food & Beverage Industry

In the food & beverage industry, all components must comply with hygiene and safety standards such as FDA regulations, ISO 22000, and industry guidelines like EHEDG (Europe) or 3-A SSI (U.S.). By helping achieve these standards, CNC machining promises that parts used in this sector are durable, easy to clean, and contamination-free.

- Works with food-grade materials like stainless steel, aluminum, and plastics like PEEK

- Offer surface finishes needed for dairy and sterile drinks (Ra ≤ 0.8 µm & Ra ≤ 0.4 µm)

- Prevent bacterial growth when combined with electropolishing

- Allows customization for different food processing lines

- Supports mass production of molds and packaging equipment for global FMCG companies

Key Applications of CNC in Food & Beverage

| Area | CNC Examples | Why It Matters |

| Processing Equipment | Blades, mixers, augers | Offer efficient and consistent food processing. |

| Beverage Machinery | Pump parts, bottling nozzles, valves | Maintains hygiene and precision in bottling. |

| Food Packaging | Plastic bottle molds, cans, containers | Produces uniform packaging quickly and accurately. |

| Dairy Industry | Housings for pasteurizers, separators, filling machines | Improves reliability and reduces contamination risks. |

| Bakery & Confectionery | Chocolate molds, dough cutters, and shaping dies | Maintains product consistency and quality. |

| Quality & Safety Equipment | Casings for sensors, scanners, and quality control devices | Protects sensitive equipment and guarantee food safety. |

Real-World Case Studies

- Nestlé (Worldwide): Operates over 600 CNC-enabled factories, decreasing energy consumption by 22%.

- Cadbury (Mondelez): CNC machining chocolate molds reduces production time by 30%, leading to faster and more flexible product innovation.

20. Plastic & Polymer Industry

Plastics and polymers are one of the most versatile materials available today, relating to millions of products. CNC machining is essential to:

- Creating molds and dies with a level of precision in microns (±0.025 mm).

- Machining engineering plastics like ABS, nylon, PEEK, and PTFE, where ABS alone accounts for 25% of all CNC-machined plastics.

- Cost-effective mass production (as opposed to multiple setups) helps you reuse the molds, saves time, and improves output.

CNC machining creates precision while enabling versatility and productivity in the plastics industry.

Key Applications of CNC in the Plastic & Polymer Industry

| Application Area | CNC-Machined Parts/Tools | Why CNC Is Important |

| Injection Molding Dies | Steel/aluminum molds for automotive parts, toys, packaging | High-precision molds for consistent quality and repeatable production |

| Extrusion Tools | Dies and heads for pipes, sheets, films | Allows accurate shaping of long-run products with uniform dimensions |

| Prototype Manufacturing | Plastic prototypes for consumer goods and electronics | Enables rapid, precise prototypes for testing and design validation |

| Thermoforming Molds | Forming dies for trays and containers | Produces durable molds with precise contours for packaging applications |

| Plastic Machined Parts | PEEK, PTFE, nylon, and Delrin components for medical and aerospace use | Facilitates complex, high-performance parts directly from raw plastics |

| Consumer Goods | Housings, casings, accessories | Offers custom, consistent, and scalable parts for everyday products |

Real-World Case Studies

- LG Chem (South Korea): Producing 1.6M+ tons of ABS plastics/year, using CNC for plastic molds in automobiles and electronics, with strong R&D for cost and supply stability.

- BASF (Germany): Using CNC for prototypes and specialty plastics in automobiles, construction, and electronics, enabling rapid iterations and accurate production for global demand.

- Nilkamal (India): Using CNC molds for furniture, crates, and goods, supporting India’s plastics market that costs USD 479B (2024, CAGR 5.76%).

21. Renewable Battery & EV Manufacturing

Electric vehicles (EVs) and renewable batteries require components to be lightweight, heat-resistant, or precision-machined. From battery cells to the electric drivetrain, CNC machining is a key part because it does the following:

- Uses lightweight alloys (aluminum, titanium, and magnesium) that cut vehicle weight by 30–50%, boosting range by 6–8% per 10% reduction.

- Machines, motors, and transmissions with a tolerance of 50 µm for high performance.

Key Applications of CNC in the EV & Battery Industry

| Area | CNC Examples | Why It Matters |

| Battery Components | Housings, cooling plates, connectors | Safe battery operation and thermal management. |

| Electric Motors | Rotor shafts, stator housings, gears | Delivers precision for smooth motor performance and efficiency. |

| Power Electronics | Enclosures for inverters, converters, controllers | Protects sensitive electronics and maintains durability. |

| Chassis & Structural Parts | Aluminum frames, suspension components | Provides lightweight strength for vehicle stability and safety. |

| Thermal Management | Cooling channels, plates | Prevents overheating and prolongs battery and motor life. |

| Charging Infrastructure | EV charger housings, connectors | Durability and reliability in charging stations. |

Real-World Case Studies

- Tesla (USA): Gigafactories are 95% automated and produce a Model Y every 30 seconds. CNC machining is used for battery casings and housings in the production of over 2 million vehicles by 2024.

- Tata Motors (India) & BYD (China): They utilize CNC for EV drive trains, battery housings, and connectors, giving precision, durability, and scalability in their electric vehicle production.

- Ola Electric (India): Uses CNC to develop battery housings and frames for their e-scooters, achieving quick scaling and better quality while minimizing material waste.

- BYD (China) & Ola Electric (India): Use CNC to produce battery housings, connectors, and frames for their e-scooters.

22. Education & Research Labs

CNC machines in universities, R&D centers, and training institutes are primarily used for education and innovation, rather than mass production. They offer students and researchers several benefits that help them gain practical experience with modern manufacturing methods.

Key Applications of CNC in Education & Research

| Application | CNC Use | Why It Matters |

| Student Training | Learning programming and basic machining | Hands-on experience for practical skills |

| Prototyping & Innovation | Creating prototypes for robotics, aerospace, automotive | Quick, accurate models for projects |

| Material Research | Testing new alloys, composites, biomaterials | Helps evaluate and understand materials |

| Industry Collaboration | Partnering with companies on CNC solutions | Brings research into real-world applications |

| Maker Labs & Startups | Developing first product prototypes | Supports new ideas and entrepreneurship |

Real-World Case Studies

- IIT Madras (India): Has a 5-axis CNC center (with a tolerance of 1-micron) and trains 8,300 students/year by offering CNC research with aerospace, automotive, etc.

- MIT (USA): Uses CNC in Fab Labs for robotics, prosthetics, and micro-machining applications so that hundreds of students/researchers can access and engage with CNC firsthand every year.

- NIT & Engineering Colleges (India): Expanding CNC labs for actual training experiences, improving student skills, employability, and industry training readiness.

23. Consumer Electronics (Smartphones, Laptops)

Smartphones, laptops, and wearables demand compact, attractive, and dependable parts. In a space that is driven by design, performance, and volume, CNC machining is vital because it:

- Makes enclosures to ultra precision with tolerances of ±0.001 mm.

- Produces lightweight parts that keep devices under 200 g.

- Provides micron-level accuracy (±0.01–0.02 mm) that addresses function and user experience.

Key Applications of CNC in Consumer Electronics

| Product Area | CNC Application | Benefit |

| Smartphones | Unibody aluminum frames and casings | High strength, premium finish, and durability |

| Laptops | MacBook and ultrabook housings | Sleek design with precise tolerances |

| Cameras | Lens housings, camera rings, gimbal parts | Accurate alignment for optical performance |

| Heat Management | Cooling housings for processors and batteries | Efficient thermal regulation prevents overheating |

| Wearables | Smartwatch and fitness tracker casings | Lightweight, durable, and ergonomic design |

| Charging & Connectors | USB housings, connectors, sockets | Reliable connections and consistent fit |

Real-World Case Studies

- Apple (United States): Employs around 40,000 CNC machines to manufacture iPhones each day to reach 10-micron accuracy and uses 13 or more milling operations to create MacBook unibodies.

- Samsung (South Korea): Uses high-speed Fanuc Robodrill CNC machines to achieve precision in camera housings and smartphone molds in high-volume production.

- Dell (United States): Utilizes CNC machining for housing laptop shells and cooling components that are ultra-thin and strong with minimal weight.

- Boat & Noise (India): Incorporate CNC machining for their smartwatch casings and premium audio housings, achieving a balance between economic pricing and high-quality finish.

24. Architecture & Interior Design

In architecture and interiors, design accuracy is just as important as structural strength. CNC machining has become a creative enabler because it:

- The time to prototype will be 80% faster than the designing and building process.

- Provides intricate geometric forms that cannot be made with manual woodworking or stone-cutting techniques.

- Provides repeatability for modular designs like wall panels, partitions, and ceilings.

- Facilitates the speed of prototyping architectural models, as well as scaled 3D designs.

- Allows for customizations that fit bespoke luxury interiors.

Key Applications of CNC in Architecture & Interiors

| Area | CNC Application | Why It Matters |

| Decorative Panels & Partitions | Cuts MDF, plywood, and acrylic sheets into intricate patterns | Enables detailed designs that are hard to achieve by hand |

| Furniture & Fixtures | Custom cabinets, chairs, and modular fittings | Guarantee precision, repeatability, and consistent quality |

| Stone & Marble Work | Precision cutting of marble and granite | Reduces material waste and achieves flawless finishes |

| Scale Models | Architectural models for presentations | Allows an accurate miniature representation of complex designs |

| False Ceilings & Lighting | CNC-cut ceiling panels and light diffusers | Creates unique designs with precise fit and symmetry |

| Luxury Interiors | Engravings, 3D wall art, and high-end interior details | Combines customization with high-quality craftsmanship |

Real-World Case Studies

- Zaha Hadid Architects (UK): Uses CNC machining for cutting-edge designs and produces 1000s of distinctive curves.

- DLF (India): Employs CNC machines for luxury residential interiors to produce high-precision modular kitchens, panels, and partitions, while having craftsmanship and low-waste errors.

- Local Studios (Kerala, India): Used CNC machining to produce temple interiors, wood paneling, and heritage motifs, speeding up production time while also maintaining traditional craftsmanship processes.

25. 3D Printing & Hybrid Manufacturing

- Works as a finishing tool that optimally produces parts to ±0.025 mm tolerances.

3D printing, also known as additive manufacturing, is changing the process of how prototypes and items are developed. It usually creates rough surfaces and distance tolerances (±0.2–0.5 mm). But sometimes the properties are not always consistent. This is where CNC machining comes into play:

- Utilizes materials that are difficult to 3D print (metal alloys, including titanium, Inconel, and hard steel).

- It also allows for the rapid prototyping of new designs and designs plus scaling up production together to receive the best of both worlds.

Key Applications of CNC in 3D Printing & Hybrid

| Application Area | CNC Use/Examples | Why CNC Is Important |

| Surface Finishing | Polishing and trimming 3D-printed prototypes | Ensures smooth, high-quality surfaces |

| Tolerance Correction | Adjusting parts to meet tight specifications | Guarantees precise dimensions and functionality |

| Hybrid Manufacturing Systems | Combined additive (3D printing) + subtractive (CNC) processes | Speeds up production and enables complex geometries |

| Complex Metal Components | Post-processing aerospace and medical 3D-printed parts | Provides strength, precision, and compliance for critical applications |

| Custom Prototyping | Startups and R&D labs creating fast prototypes | Accelerates product development and innovation |

| Repair & Remanufacturing | Rebuilding damaged parts with 3D printing + CNC finish | Restores parts efficiently while maintaining quality |

Real-World Case Studies

- GE Aviation (United States): Achieving aerospace quality, resulting in a 40% reduction in lead times and minimizing R&D and production costs.

- Siemens (Germany): The hybrid production process of turbine blades created a 30% cost reduction and a shorter prototype-to-production cycle time.

- Indian Startups: The hybrid production system for medical implants and automotive prototypes produced designs 60% faster and reduced unit costs, increasing affordability.

Conclusion

The same precision that keeps a combine harvester running through muddy fields is what makes an aircraft turbine blade safe for thousands of flight cycles. That’s the universality of CNC.

Tomorrow, the CNC machining will not only cut metal but cut emissions too with AI-led optimization, waste reduction, and recyclable alloys. It means the future is precision with purpose when you utilize CNC machining.

If world leaders in aviation, fashion, and sports already depend on CNC, can your business afford not to? The next move is yours.

Venttup Ventures is the leading CNC machining service in India, renowned for serving the ubiquity of CNC. We supply world-class CNC-machined parts for aerospace, EV, marine engineering, and medical needs.

Our advanced approach to manufacturing, which includes sustainability, the China Plus One strategy, and indigenization, has helped several companies obtain precision parts at competitive pricing.

Do your production needs include cost reduction, eco-friendliness, and supply chain optimization? Then you match our ultimate goals. Call us now and get your blueprint transformed into parts that serve your purpose.