Learn the essentials of Aluminium Die Casting, including process, benefits, alloys, and common applications.

Table of Contents

If you’re new to aluminium die casting, you might be surprised by how common it is in everyday products. This process lets you make strong, detailed metal parts quickly and in large numbers. Basically, it works by pushing melted aluminium into a steel mold using high pressure. Once it cools, you get a part that’s ready for finishing or even direct use.

In this article, you’ll get the basics on how aluminium die casting works, what it’s good for, its limits, and what you should think about if you want to use it for your own projects.

Key Takeaways

- Aluminium die casting uses high pressure to force molten metal into a mold, creating detailed and accurate parts.

- This process is great for making lots of parts quickly, especially when you need them to look and fit the same every time.

- Choosing the right alloy and mold design is important for strength, weight, and how the part will be used.

- Aluminium die casting stands out for its speed and surface finish compared to other casting methods like sand or permanent mold casting.

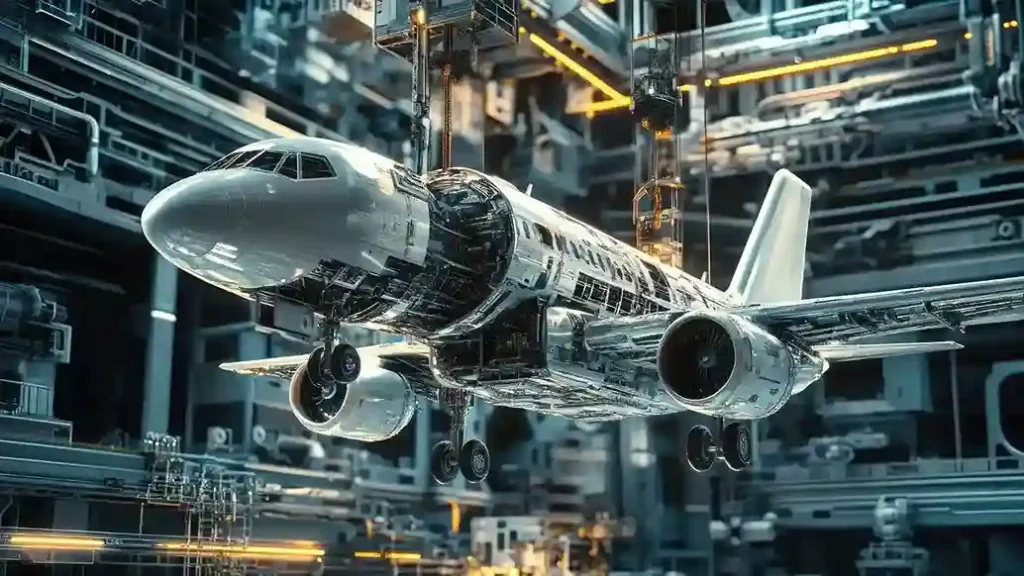

- Industries like automotive, aerospace, and electronics rely on aluminium die casting for lightweight, reliable parts.

Understanding the Aluminium Die Casting Process

When you think about producing precise, complex metal parts at scale, the aluminum casting process in India and across the globe often starts with die casting. This technique shapes the industry, especially when tight tolerances or detailed features matter most.

How the Die Casting Method Works

Aluminum die casting works like this: you take aluminum alloy and heat it until it’s fully melted. That molten metal is then forced, under high pressure, into a steel mold (called a die), which has been shaped to match the final part. The pressure makes sure every detail, even super-thin parts, gets filled in.

- The die has two halves: one stays put, the other moves so finished parts can pop out.

- Once the aluminum cools and solidifies—usually in seconds—the halves open up and out comes a part with a clean surface.

- Die molds can handle thousands of cycles before they need to be swapped, making this great for high-volume runs.

Precision and repeatability are key features that make aluminum die casting the preferred choice for applications demanding mass production and fine details.

Role of Cold Chamber Machines

Aluminum melts at a temperature that’s too much for most machines, so cold chamber die casting is standard. Here’s what happens:

- The metal is melted in a separate furnace.

- It’s ladled into a shot chamber that sits outside the main machine.

- A piston injects the molten aluminum into the die under intense pressure.

This method protects the machine from heat damage and allows for casting alloys that need higher melt temps. Cold chamber machines also keep things running smoother for tougher jobs, as used by seasoned manufacturers like Venttup Ventures handling complex component orders.

Cycle Stages from Mold to Final Product

The whole process is pretty systematic, with every cycle broken down like this:

| Stage | What Happens? |

|---|---|

| Die Preparation | Lubricate mold, close halves |

| Metal Injection | Inject molten aluminum |

| Cooling | Metal solidifies in the die |

| Ejection | Open die, remove the part |

| Trimming | Cut away any excess |

Each of these steps is set up for speed and energy efficiency, so while the upfront tooling cost is high, it pays off in the long run for big orders.

In India, where demand for lightweight, durable parts is always growing, the aluminum casting process continually adapts to new standards and design requirements. You’ll often see companies running multiple casting lines and tweaking their cycle stages to speed up turnaround and keep costs down.round and keep costs down.

By mastering each stage of aluminum die casting, you’ll get the accuracy, repeatability, and cost savings crucial for modern manufacturing.

Key Advantages and Limitations of Aluminium Die Casting

Aluminium die casting is pretty popular for making all sorts of parts, especially when you need a lot of them, fast. If you’re considering the advantages of aluminum casting technology, it’s important to see both sides—the good and the not-so-good.

Benefits for High-Volume Production

- Speed: Once the die is set up, each cycle is fast, so you get thousands of parts in a short time.

- Cost per part drops as volume goes up, making big runs affordable.

- Consistency is solid—every part is nearly identical, which is great if you need tight tolerances or intricate designs.

- Suitable for complex shapes that are tricky with machining or other types of casting.

- Minimal post-processing is needed because the parts come out with a smooth finish.

| Feature | Impact |

|---|---|

| Cycle Time | Short—seconds to minutes |

| Tolerance Capability | Tight (±0.05mm or better) |

| Suitable Production | High volume |

| Strength-to-Weight | Very good for many applications |

You’ll often find industries like automotive and electronics picking die casting for these reasons: speed, repeatability, and cost savings for big quantities.

Surface Finishes and Corrosion Resistance

- Die-cast aluminum has a smooth surface right out of the mold; decorative and protective finishes are easy to apply.

- Aluminum doesn’t rust; instead, it forms a thin oxide layer that actually protects the metal under normal conditions.

- You can bead blast, anodize, powder coat, or paint these parts depending on what you need.

Common Challenges and Limitations

- The initial cost is high—custom dies are expensive to make and only make sense if you need a lot of parts.

- Not ideal for small runs because the die and setup costs won’t pay off.

- Thin or complicated features might warp if not carefully designed, and it can be tricky to cast parts with different wall thicknesses.

- Some internal cavities or super fine details are tough to achieve—there are still limits compared to 3D printing or machining.

Here’s a quick breakdown:

- High upfront tooling cost

- Not practical for low quantities

- Limits on certain feature sizes or depths

If you’re looking for something that can pump out lots of parts quickly with reliable strength and fine details, aluminum die casting is a smart call. But if you only want a limited number of pieces, the startup costs might not make sense.

Design Considerations for Aluminium Die Casting Parts

When you’re getting into aluminum die casting, design decisions matter a lot for both quality and cost. It’s easy to skip right to CAD files or prototypes, but step back — think about how your choices affect not just a single part, but the whole production line.

Optimizing Mold Design and Parting Lines

Start by thinking about the mold. Every mold opens and closes along what’s called the parting line. You need to plan this carefully so your part comes out smoothly — otherwise, you’ll end up with visible seams or even damage when removing the piece. Mold complexity, including sliders or cores for odd shapes, drives both tooling time and cost.

- Always define the parting line with the final shape and function in mind.

- Use draft angles wherever possible (around 2° is standard) to help with ejection from the mold.

- The placement of the parting line influences both surface appearance and post-processing needs.

A small oversight in the mold design can lead to expensive fixes later.

Importance of Injection Points

Where the molten aluminum enters the mold — the injection points — determines fill quality and consistency. With a simple part, one entry might be enough. More complex shapes may need multiple injection points to avoid incomplete fills or weak spots.

- Multiple gates can solve issues with long flow paths but can leave more marks on the part.

- The right location helps evenly distribute metal and reduces the risk of air pockets or cold shuts.

- Too few injection points can slow down the process or force aluminum through tiny paths, leading to defects.

For more, manufacturers like Venttup connect clients with experienced die casting partners, who can advise on the best gate locations and prototype options if you’re unsure.

Wall Thickness and Structural Factors

Wall thickness isn’t just about strength — it’s also about avoiding defects like warping or shrinkage. Consistency is king. Sudden changes can cause stress during cooling.

| Feature | Recommended Thickness (mm) | Notes |

|---|---|---|

| Exterior Walls | 2.0 – 3.5 | Go thinner only if necessary |

| Ribs | 1.5 – 2.5 | Should be 50-75% of main wall |

| Bosses | 2.0 – 3.5 | Avoid thick concentrations |

- Try to keep walls uniform across the part.

- Thinner walls use less material and cool faster, but too thin can increase rejects.

- If you need more support, reinforce with ribs rather than simply thickening the wall.

Designing for aluminum die casting means balancing complexity, manufacturability, and budget — every adjustment in the early stages saves headaches when it’s time for full-scale production.

Comparing Aluminium Die Casting to Other Metal Casting Methods

Understanding how aluminum die casting stands up against other casting techniques is important before picking a process. You want your parts to be reliable, produced quickly, and, of course, affordable over the long run. Let’s break down some of the main comparisons you should keep in mind.

Green Sand Casting vs. Die Casting

Green sand casting is often seen as the go-to for small batches. The sand molds can be put together quickly, which means you don’t spend much on tooling up front. But these molds wear out quickly and the finished parts need more work afterwards. Die casting, on the other hand, is best when you’re making high volumes of parts—think thousands, not dozens. The cost per part drops as you scale up, and it’s much easier to get consistent dimensions each time.

| Feature | Green Sand Casting | Aluminium Die Casting |

|---|---|---|

| Mold Material | Sand | Steel (permanent) |

| Setup Cost | Low | High |

| Suitable Volume | Small to medium runs | High-volume production |

| Surface Finish | Rough | Smooth |

| Tolerance | Moderate to poor | Tight |

| Typical Wall Thickness | Thick | Thin |

- Die casting lets you skip a lot of the cleaning and machining after casting.

- Sand casting is more flexible if you need very large or complex parts.

- Die casting needs more upfront investment but pays off if you’re looking at mass production. For more detail, see this perspective on die casting’s cost-effectiveness for high-volume production.

Permanent Mold Casting Differences

Permanent mold casting uses reusable molds—kind of like die casting—but the metal is poured in without pressure, just gravity. This process sits in the middle: more durable than sand molds, less complex tooling than die casts. The surface finish and part strength can be better than sand-cast pieces, but you sacrifice some of the finer detail that die casting can achieve.

- Suitable for medium volumes and simpler shapes

- Doesn’t achieve the thin walls or high detail possible with die casting

- Stronger than sand-cast parts, but usually costlier per piece than die cast parts at high volumes

If you’re stuck between methods, think about your production needs. Smaller runs lean toward sand, mid-range favors permanent molds, high volume points straight to die casting.

Die casting needs more upfront investment but pays off if you’re looking at mass production. For more detail, see this perspective on die casting’s cost-effectiveness and why it’s a key factor in choosing the right method.

Why Choose Aluminium Die Casting

So, why would you pick die casting above the other options? Here’s what sets it apart:

- Incredible speed for large production runs

- Consistently high-quality parts, every cycle

- Tight tolerances and smooth finishes, right out of the mold

- Reduced waste with minimal need for secondary machining

- Strong, lightweight parts — a signature of aluminum

In short, if you need a lot of parts made quickly and you want every part to be near-identical, die casting is often the best answer. The upfront cost seems high, but the savings show up fast when you scale up production volumes. For readers wondering how to choose between casting processes, die casting is the go-to for high-volume, precision needs.

Popular Aluminium Alloys Used in Die Casting

Aluminium die casting isn’t just picking any old metal blend and hoping for the best. When you’re choosing alloys for automotive aluminum cast components or electronics, there’s a set of tried-and-true options. Each one brings something different to the table, whether it’s better corrosion resistance, strength, or ease of molding.

Characteristics of Common Alloys (A380, A360, B390, A413)

- A380: This is probably the most widely selected alloy for die casting. It gives you a handy mix of solid mechanical strength, good fluidity (helpful when you need to fill complex molds), and it isn’t too hard on the wallet. You’ll see it pop up in power tools, furniture parts, and lots of chassis and cases.

- A360: Known for its great corrosion resistance and pressure tightness. Its high fluidity makes it perfect when you’re working with thin sections or seeking that detailed finish. Think of automotive controller housings and oil pans—A360 gets the job done there.

- B390: If you need high surface hardness and wear resistance, B390 is your go-to. Downsides are lower ductility, but that hardness is just what you want for things like engine blocks.

- A413: This alloy shines when you need pressure tightness, especially in things like hydraulic cylinders. A413 also offers excellent corrosion resistance due to its unique blend.

Here’s a quick comparison:

| Alloy | Notable Properties | Typical Uses |

|---|---|---|

| A380 | Castability, cost, strength | Gearbox housings, brackets |

| A360 | Corrosion resistance, fluidity | 5G boxes, oil pans |

| B390 | Hardness, wear resistance | Engine blocks |

| A413 | Pressure tightness, corrosion resistance | Hydraulic cylinders |

For more on unique alloys like A383, which offers even greater fluidity and is useful for thinner, intricate die casting designs, check out this page about aluminum alloys for casting.

Selecting the Right Alloy for Your Application

So, what should you look at before deciding?

- Required strength and flexibility of your part

- The part’s operating environment (think: exposure to moisture or chemicals)

- Cost targets

- Dimensional needs—thinner or more intricate parts need better fluidity

Your choice will impact not just the casting process, but the part’s long-term reliability and quality. It’s a good strategy to match the alloy’s properties to your end-use, whether it’s automotive or home electronics. This also ties into the future of aluminium die casting in EV, where lightweight alloys play a crucial role.

Mechanical and Chemical Properties Impact

When alloys are on the table, keep an eye on:

- Tensile Strength

- Hardness (measured in Brinell or Rockwell)

- Elongation and flexibility

- Corrosion resistance

- Thermal conductivity

Picking an alloy just for cost might save a bit upfront, but the wrong choice can cause headaches with durability or finish quality down the road—especially for automotive aluminum cast components.

Aluminium alloys in die casting really open up choices, as each blend has strengths for different product needs. Understanding the main types will help you get a result that works for your real-world applications—and saves you time fixing problems later.

Finishing and Post-Processing Options for Die Cast Aluminium Parts

When your aluminum die castings come out of the mold, they look almost done—but there’s still some work required before they’re ready for the final application. The post-processing and finishing steps you pick can really shape both how the part performs and how it looks in the end.

Finishing and post-processing might sound like minor details, but they can have a big impact on durability, looks, and how well your part works over time. Take the time to pick the right methods—you’ll notice the difference in the end result, especially as sustainable manufacturing practices become more important.

Deburring and Surface Smoothing Techniques

Straight from the mold, die cast parts can have rough edges or seams, known as flash, that need to go. You can remove these by:

- Trimming: Cutting away extra metal bits manually or with a press.

- Vibratory tumbling: Using a machine filled with abrasive media to knock off sharp edges.

- Sanding or blasting: Smoothing the surface using sandpaper or blasting media, which also preps the part for coatings later.

Attention to deburring and smoothing is what keeps your finished part from feeling sharp or looking unfinished.

Coating and Painting Methods

A big part of finishing aluminum die castings is protecting them and sometimes adding color or a slick appearance. Choices include:

- Powder coating: Sprayed as a dry powder then baked on, this finish is tough, comes in many colors, and resists scratches.

- Anodizing: Makes parts even more corrosion-resistant and gives a hard, non-conductive surface. You’ll get a matte, consistent look, usually in metallic shades.

- Chem film (chromate conversion): Adds a thin, electrically-conductive protective layer—it’s often used when electrical contact is still needed.

- Liquid painting: Sprayed or dipped paint that offers color variety and shine, but not quite as durable as powder coating.

| Finish Method | Durability | Color Options | Electrical Conductivity |

|---|---|---|---|

| Powder Coat | High | Wide Range | No |

| Anodizing | High | Limited | No |

| Chem Film | Medium | Light Tint | Yes |

| Liquid Paint | Medium | Extensive | No |

Machining and Further Modifications

Once casting is done, some features just can’t be molded accurately and require a bit more work:

- CNC machining: For holes, threads, or tight tolerances that the die can’t deliver.

- Drilling or tapping: Essential for adding threaded holes for fasteners.

- Custom engraving: Great for part numbers or branding, usually done with laser or mechanical etching.

These steps come after smoothing and finishing, so you don’t risk damaging pretty coatings or freshly cleaned surfaces.

Finishing and post-processing might sound like minor details, but they can have a big impact on durability, looks, and how well your part works over time. Take the time to pick the right methods—you’ll notice the difference in the end result.

Conclusion

So, that’s the basics of aluminum die casting. If you’re thinking about making a lot of metal parts that need to be strong, lightweight, and pretty detailed, this process is worth looking into. Sure, the upfront costs for making the molds can be high, but once that’s done, you can make thousands of parts quickly and with less waste.

Plus, there are plenty of finishing options if you want your parts to look a certain way or need extra protection. Just remember, it’s best for bigger production runs because of the tooling costs. If you need just a few parts, other methods might make more sense. But for high-volume jobs, aluminum die casting is a solid choice that many industries rely on every day. And with new technologies like AI automation in aluminium die casting, the process is only getting faster, more efficient, and smarter.

Partner with Leading Aluminum Die Casting Experts

If you’re exploring aluminium die casting for your projects, working with the right partner makes all the difference.

Venttup Ventures is one of the best aluminum die casting manufacturers in India, delivering precision, scalability, and innovation for businesses across automotive, aerospace, EV, electronics, and other industries.