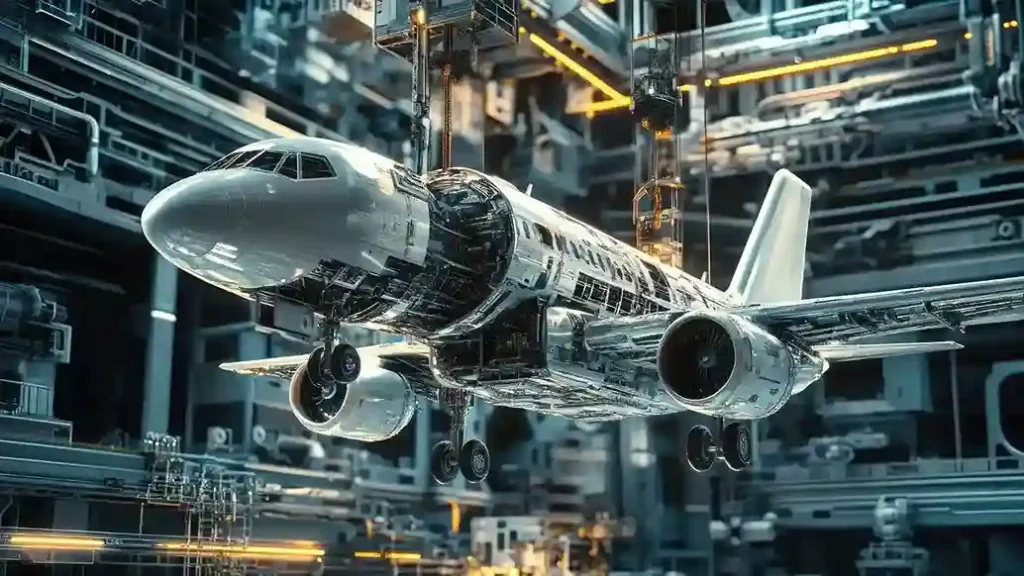

Reducing Carbon Emissions: Sustainable Manufacturing Best Practices for Aerospace Firms Sourcing from India

Have you ever wondered why aerospace manufacturing has such a high carbon footprint? Behind every precision-engineered component are energy-intensive machining processes and long, global supply chains. While aerospace is one of the most advanced manufacturing industries, it also relies heavily on power-hungry production and complex logistics — making it one of the most carbon-intensive sectors. […]

Case Study: Investment Casting Development for Precision Engineering Components

Industry Engineering Design & ManufacturingInvestment Casting | Precision Components Project Overview The client operates in the industrial machinery sector, supplying precision components for high-load mechanical systems. The leading precision engineering company required high-accuracy mechanical components for their machinery systems. The components included cone gears, cam plates, and trip parts, all of which demanded tight tolerances, […]

How Reverse Engineering Services Work in India – Step by Step (With Use Cases)

Have you ever faced a situation where a part failed, the original supplier was unavailable, and no drawings existed – leaving production on hold?Many manufacturers in India deal with this daily, especially when parts are imported, obsolete, or not supported by the OEM anymore. Good news: reverse engineering services help solve this exact problem by […]

Precision Component Manufacturing for Defense Machinery

Customer Defense Machinery – Industrial Automation Product Copper Rotors & Motor Shafts Industry Defense – Precision Engineering & Manufacturing Project Overview A customer in the defense machinery sector approached Venttup to develop Copper Rotors and Motor Shafts for high-precision industrial machinery. The components were critical for supporting key mechanical operations, requiring tight dimensional tolerances, superior […]

Localisation of Capacitor Tilt Trolley

Customer Energy Sector – Power & Manufacturing Product Tilting trolley Industry Power & Energy — Manufacturing Project Overview The customer relied on a capacitor tilting trolley that was previously imported from Europe. As production demand increased, the team required additional units but faced challenges such as long lead times, high import costs, and slow supply […]

What Is Reverse Engineering Services? A Complete Guide for 2026

Have you ever looked at a product and wondered, “How did they make this — and can I recreate it?” That’s exactly what reverse engineering services help you do. Reverse engineering is the process of analyzing and reproducing an existing product, part, or system by studying its design, materials, and functionality. In simple terms — […]

Real Benefits Of Die Cast Aluminium

Discover the real benefits of die cast aluminum: fast production, strong parts, complex designs, lightweight, and smooth finishes. Learn why it’s ideal for many industries. Thinking about making a lot of parts—fast, strong, and cost-effective? Die-cast aluminium delivers rapid cycles, high strength-to-weight, thin-wall precision, and smooth, near-net finishes. It’s ideal for complex shapes and high […]

Aluminium Die Casting: The Basics You Should Know

Learn the essentials of Aluminium Die Casting, including process, benefits, alloys, and common applications. If you’re new to aluminium die casting, you might be surprised by how common it is in everyday products. This process lets you make strong, detailed metal parts quickly and in large numbers. Basically, it works by pushing melted aluminium into […]

25 Industries Revolutionized by CNC Machining: Real-World Applications You Can’t Ignore

The global CNC (computer numerical control) machine market size is expected to have a CAGR of 9.9%, resulting in the growth level reaching USD 195.59 billion by 2032, from 101.22 billion in 2025 (Fortune Business Insights). CNC machining has become the most used machining method in the world by automating the long process of manufacturing […]

Best 6 Materials for CNC Machining in India: [Practical Guide]

Do you find it hard to balance machinability, strength, and budget when selecting materials for your CNC projects? Then you’re not alone. The need for precision-manufactured equipment is very high in India. Our country relies on this expensive manufacturing method to create accurate parts. But there are a lot of risk factors involved in it. […]