Discover the real benefits of die cast aluminum: fast production, strong parts, complex designs, lightweight, and smooth finishes. Learn why it’s ideal for many industries.

Table of Contents

Thinking about making a lot of parts—fast, strong, and cost-effective? Die-cast aluminium delivers rapid cycles, high strength-to-weight, thin-wall precision, and smooth, near-net finishes. It’s ideal for complex shapes and high volumes across automotive, aerospace, industrial, and electronics. Below, see real benefits, alloys, DFM tips, finishes, use-cases, and a quick takeaway.g vehicle parts.

Key Takeaways

- You can make tons of parts really quickly with die casting, which means lower prices for you.

- The parts end up strong and tough, able to handle a lot of wear and tear.

- It’s great for making complicated shapes with a lot of detail, even thin bits.

- These parts are light but still really strong, perfect for things that need to move.

- You get a pretty smooth finish right out of the mold, saving you extra work.

What Is Aluminium Die Casting?

Aluminium die casting injects molten aluminium into a hardened steel mould at high pressure. The metal fills every feature, solidifies fast, and ejects quickly—enabling high output, repeatability, and thin-wall precision. Because the process creates a dense, uniform structure, parts are rigid, durable, and dimensionally consistent.

Benefits That Matter

Fast, Repeatable Production (Lower Cost per Part)

When you need hundreds or thousands of identical parts, die-cast aluminium shines.

- Rapid cycle times: melt → inject → cool → eject → repeat.

- Less finishing: parts often come out near-net, so less grinding, sanding, or polishing.

- Built for mass production: robust moulds run for many cycles—great for steady demand and reliable supply.

Strong & Tough Parts

Die casting packs aluminium into the mould under high pressure, creating a dense structure with few voids.

- Excellent rigidity: parts hold shape under load and stress.

- Durability: ideal for components facing vibration, heat cycles, or heavy use.

- Good electrical & thermal conductivity: helpful for electronics and heat management.

- Practical outcomes: resists cracking, handles loads, lasts longer—saving time and money.

Precision for Complex Designs

High pressure forces metal into every nook and cranny of the mould.

- Tight tolerances: consistent, batch after batch—great for assemblies.

- Thin walls & intricate features: ribs, bosses, fine textures are achievable.

- Design freedom: make parts as-cast with minimal machining.

Lightweight Yet Mighty

Get the best of both worlds: high strength-to-weight and robust performance.

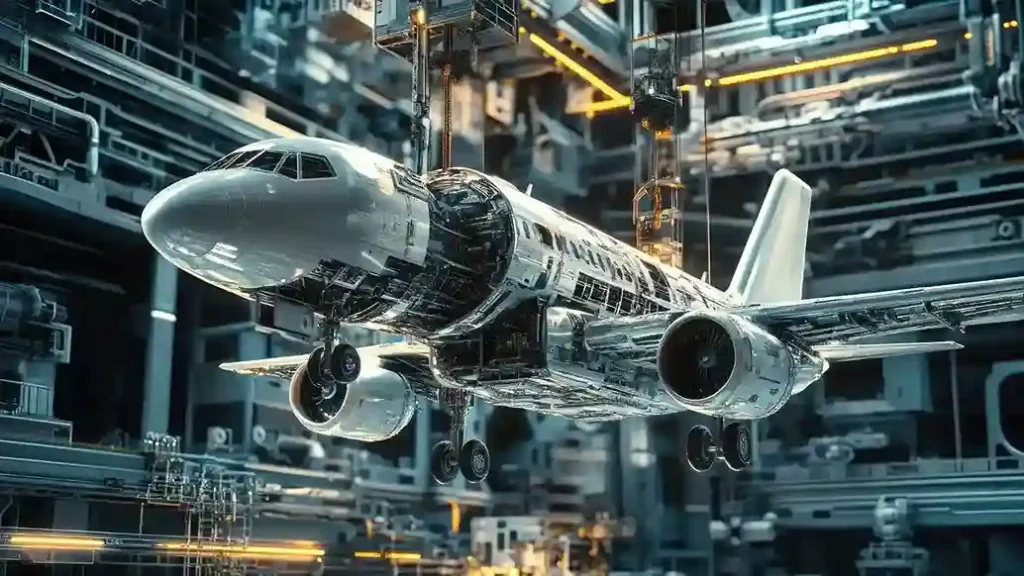

- Vehicles & aerospace: lighter components improve efficiency and range.

- Portable gear & tools: easier to carry, less user fatigue.

- Shipping: lighter parts reduce logistics cost.

Smooth Finishes Right Away

Die-cast surfaces are typically clean and consistent straight out of the tool.

- Save time & cost: fewer finishing steps; parts can be ready for paint/assembly fast.

- Flexible finishing options: anodising (select alloys), powder coating, e-coat, shot-blast/tumble for texture or edge smoothing.

Choosing the Right Aluminium Alloy

Alloys are aluminium plus other elements that tune flow, strength, hardness, and corrosion resistance. Pick based on geometry, environment, and cost.

Common die-casting alloys (quick guide):

- A380 / ADC12 – The all-rounders: excellent castability, solid strength, good surface finish; widely used for housings and structural parts.

- A360 – Better corrosion resistance and fluidity; good for complex/thin sections and harsher environments.

- B390 – Very hard, wear-resistant; used in demanding components (e.g., engine parts).

Tips:

- Complex shapes prefer high-fluidity alloys (A380/A360/ADC12).

- Outdoor/harsh conditions often favour A360.

- For sliding/wear surfaces, consider B390 (and downstream machining if required).

Where You’ll Find Die-Cast Aluminium

Automotive & Aerospace Components

Engine and transmission housings, brackets, structural parts—benefit from strength-to-weight and tight tolerances, improving fuel efficiency and performance.

Power Generation & Industrial Equipment

Pump housings, valve bodies, turbine-adjacent parts: need rigidity, dimensional stability, and durability under pressure/temperature.

Consumer Electronics & Appliances

Device frames and thermal housings leverage conductivity and smooth finishes, giving products a premium feel with efficient heat dissipation.

So, What’s the Takeaway?

Die-cast aluminium is a smart, scalable way to make strong, lightweight, complex parts quickly and affordably. You get repeatable precision, thin-wall capability, and ready-for-finish surfaces—ideal from small gadgets to big vehicle assemblies. That’s why it’s a go-to across industries.

Next Steps / Get a Quote

Ready to turn your design into strong, lightweight, high-volume parts?

As a MaaS aluminium die casting manufacturer in India, Venttup combines scalable production with engineering precision to deliver cost-efficient, high-quality components for global industries.

Share 3D file,, drawing & GD&T,, annual volume,, alloy,, finish,, critical tolerances/quality needs.

We’ll review your DFM, recommend the best aluminium alloy, and suggest the fastest, most cost-effective manufacturing path—from concept to large-scale production.