Reverse Engineering Services in India

Venttup brings a wealth of experience in advanced reverse engineering services in India, helping businesses recreate obsolete parts, damaged components, and prototypes into production-ready, high-accuracy outputs.

Get a free reverse-engineering assessment

By combining techniques such as 3D scanning to CAD reconstruction, PMI analysis we assure every step is precise, secure, and reliable – while also supporting sustainable manufacturing and resource efficiency.

Our reverse engineering process not only ensures technical precision and design feasibility but also empowers industries with cost-effective localization and component development, improved part performance, and reduced lead times.

Why Choose Venttup for Reverse Engineering India?

Complete Workflow

We handle everything from 3D scanning to CAD, simulation, prototyping, and final manufacturing using our MaaS and localization capabilities.

Proven GATE Governance

We manage every project through structured checkpoints for secure, auditable and transparent delivery.

Technical Proficiency

Provides 3D scanning, PMI Analysis, Hardness testing and compliance labs for assured accuracy.

Sustainable Impact

Our approach extends equipment life, reduces waste, and supports localization — cutting costs while making supply chains greener.

Global-ready deliverables

We deliver outputs in 3D CAD formats such as SolidWorks, CATIA, Creo, AutoCAD, and Inventor, along with comprehensive 2D manufacturing drawings featuring GD&T, ensuring global compatibility and manufacturing readiness.

Trusted & Confidential

All projects are backed by strict NDAs and secure data transfer protocols to protect your intellectual property.

Serving Diverse Industries

Venttup Ventures is the leading B2B sourcing company in India that provides sustainable Indian products for various sectors in India and around the world.

Precision Measurement Tools

For mechanical and industrial reverse engineering, manual instruments capture exact physical dimensions:

digital vernier calipers, digital micrometers, height & depth gauges, radius gauges, and angle gauges—ensuring

precise inputs for accurate digital models.

Deliverables: Dimensional notes, measurement logs

3D Scanning & Digitalization

Advanced portable and lab-based 3D scanners capture complex curves and micro-features to produce high-accuracy

point-cloud data for CAD reconstruction. On-site scanning and sample drop-off options are available.

Deliverables: Raw point-cloud data, scan reports, metrology lab notes

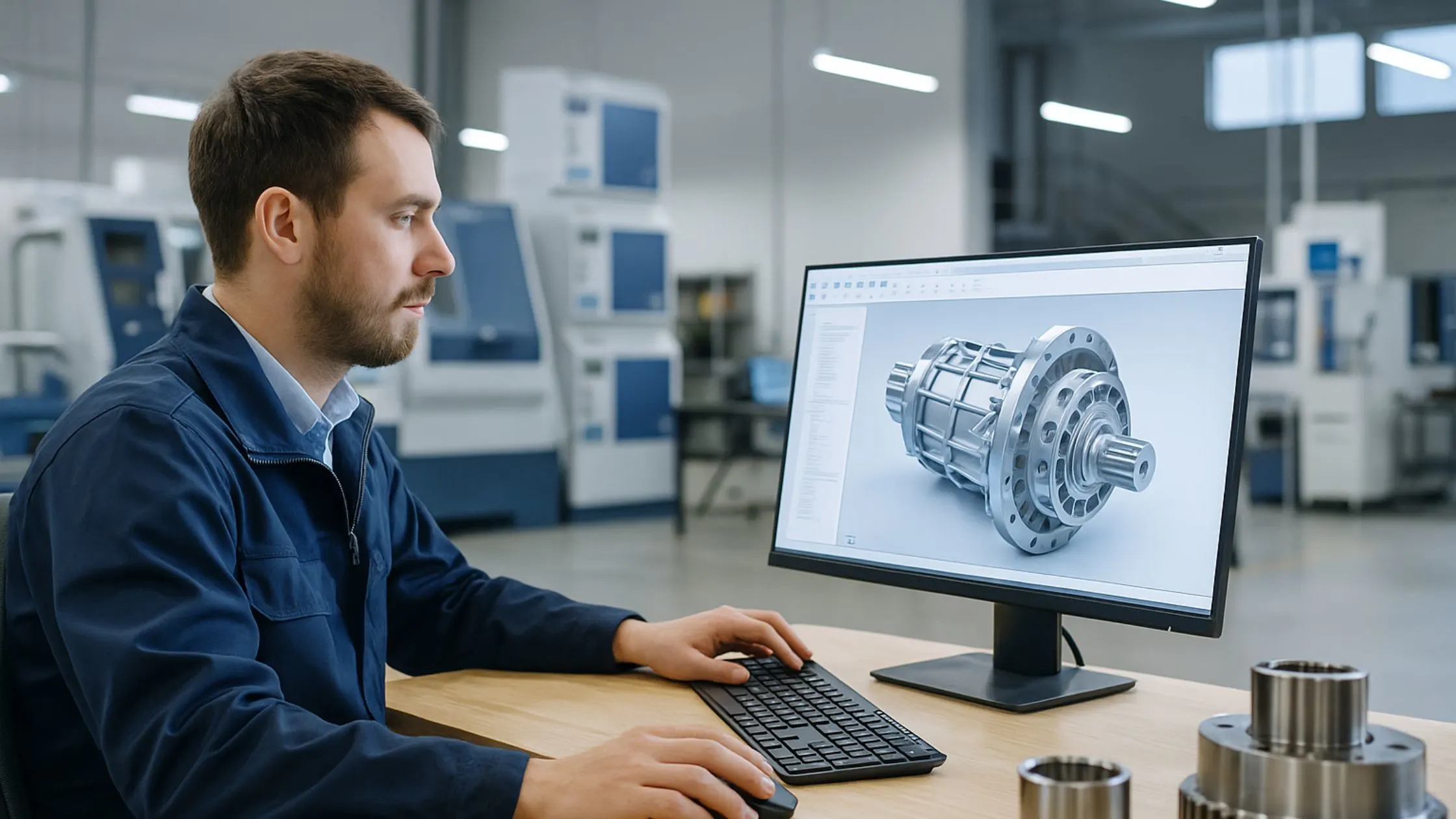

CAD Reconstruction (Parametric Modeling)

Mesh/scan data is converted into editable, feature-based, fully parametric CAD models compatible with SolidWorks,

CATIA, and Creo. 2D drawings with GD&T ensure manufacturing readiness and reuse.

Deliverables: 3D CAD files and 2D manufacturing drawings

Positive Material Identification (PMI)

Non-destructive verification of alloy composition via XRF/OES to meet specs, prevent mix-ups, and comply with

safety standards—applicable across oil & gas, energy, power, defense, and aerospace.

Deliverables: PMI reports, material certificates

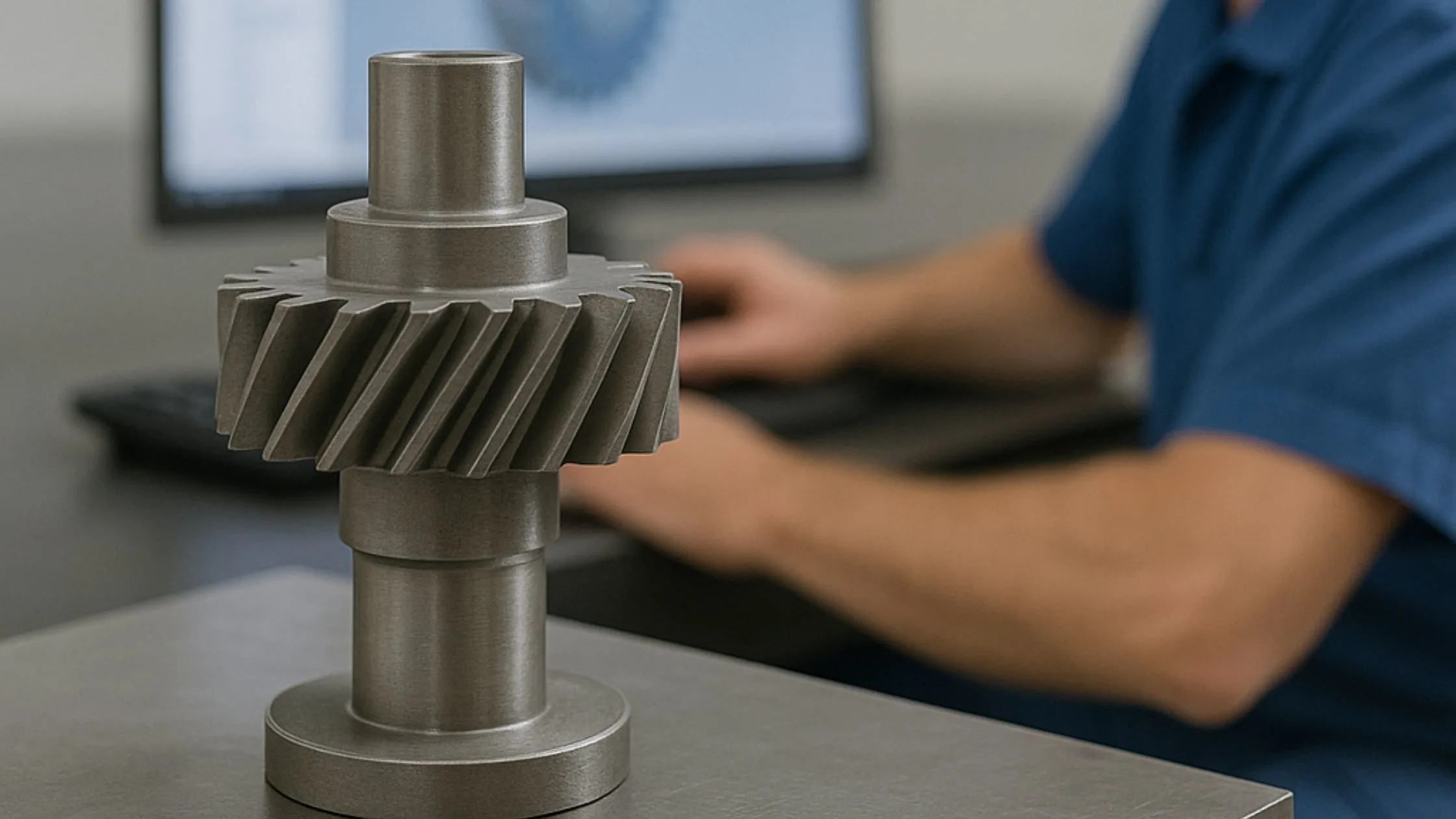

Material Hardness Testing

Determines resistance to permanent deformation by measuring indentation under controlled load. Indicates strength,

durability, and wear resistance; helps identify base material and heat treatment.

Deliverables: Hardness testing results (e.g., HRC)

FEA & Design Optimization

Finite Element Analysis validates load, stress, and thermal behavior to reduce failure risk and optimize performance,

while preserving original design intent and manufacturability.

Deliverables: FEA validation reports, optimized CAD models (if applicable)

Prototype, Tooling & Manufacturing Handover

Prototypes and pilot parts are built for testing before production. Tooling, molds, and supplier-ready packages enable

seamless scale-up via Venttup’s MaaS ecosystem.

Deliverables: Prototype samples, tooling designs, production transfer documentation

Benefits of Reverse Engineering Services in India

Reverse Engineering Services are becoming increasingly popular across industries in India — from automotive and aerospace to manufacturing and product design. At Venttup, we use advanced 3D scanning, CAD modeling, and precision measurement tools to help businesses recreate, refine, and modernize their components with accuracy and speed.

Here are the top five benefits of choosing professional reverse engineering services in India

Recreate Lost or Obsolete Parts

Many companies struggle with discontinued parts or missing design files. Reverse engineering helps you reproduce those critical components accurately using 3D scanning and digital modeling — eliminating dependency on outdated suppliers and extending equipment life

Improve Existing Designs

Our reverse engineering process enables engineers to analyze and enhance existing products, identifying weak points and optimizing materials or dimensions. This leads to stronger, lighter, and more efficient product designs, ideal for industries focused on performance improvement.

Reduce Development Time & Cost

By using an existing physical product as the base, you can skip early-stage design cycles, leading to faster prototyping and cost-effective product development. Reverse engineering helps Indian manufacturers and innovators launch products quicker and stay competitive in global markets.

Ensure High Accuracy and Quality

With advanced 3D scanning technology and CAD modeling, every recreated part achieves precise dimensional accuracy. This ensures perfect fit, consistent performance, and reliable quality, even in complex geometries or critical applications.

Enable Digital Documentation

Reverse engineering converts your physical components into detailed 3D CAD models, creating a digital database for future use. This supports digital transformation, predictive maintenance, and efficient product redesign, helping you stay ahead in the Industry 4.0 era.

Our Process

At Venttup, every reverse engineering India project follows a structured, auditable process under our GATE governance model. This assurance is for transparency, accuracy, and secure delivery at each milestone.

Inquiry & NDA

Engagement begins with a secure NDA. Clients upload or send samples for evaluation. We assures confidentiality of samples, data, specs, reports, models, communications etc.

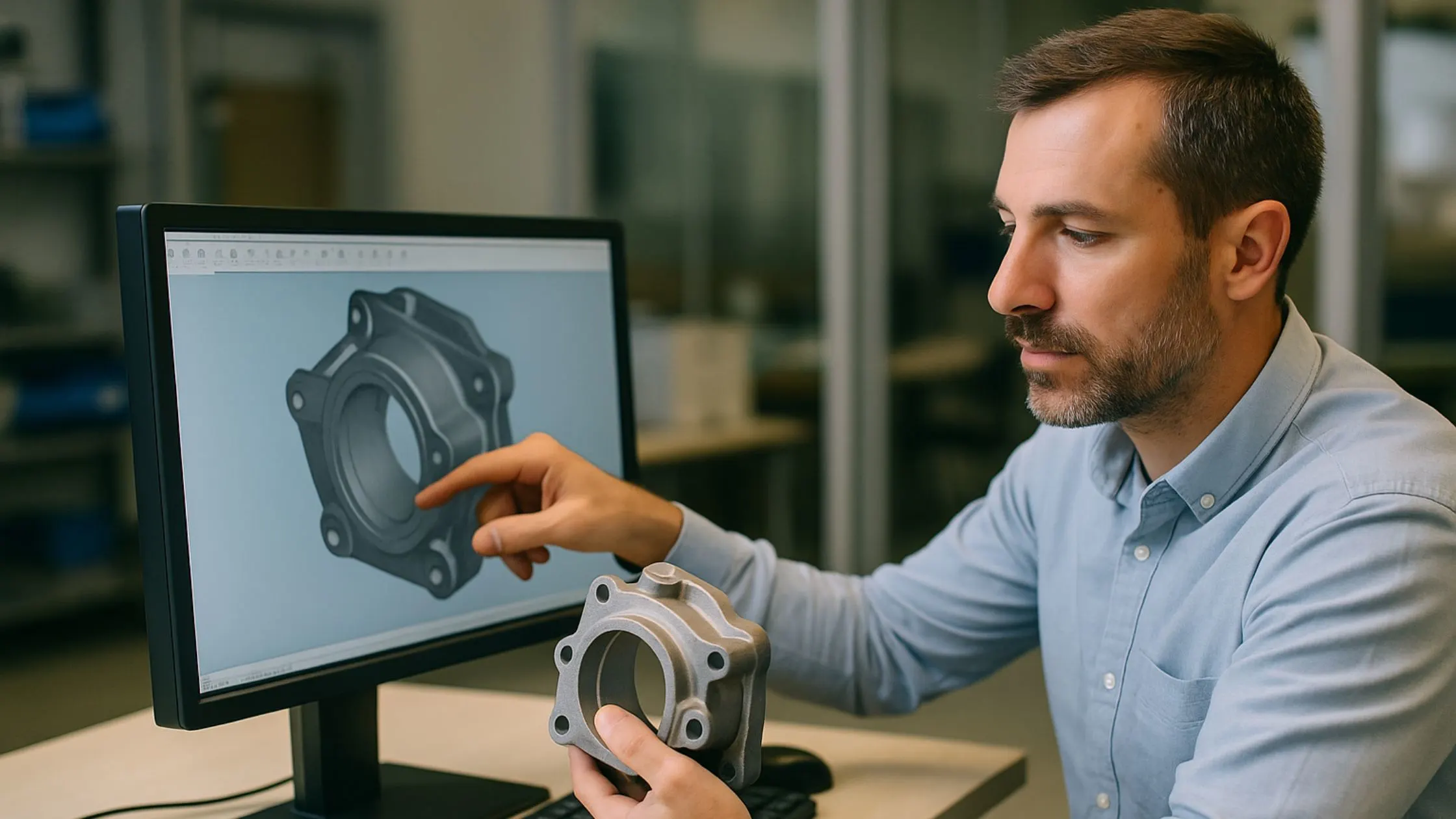

Disassembly & Inspection

We carefully disassemble components, label them, and photograph key areas. Wear patterns and assembly sequences are documented for reference and future improvements.

Measurement & Scanning

We capture exact dimensions using manual tools and high-resolution 3D scanning, generating point-cloud data for further processing.

Mesh to CAD Conversion

Point-cloud data is transformed into editable, parametric CAD models. Missing or damaged features are reconstructed to ensure manufacturability.

Material Testing & Simulation

Alloys are identified via PMI (XRF/OES), and hardness testing ensures performance standards. FEA validates load conditions, durability, and thermal behavior.

Prototype Build & Verification

Pilot parts, tooling, or 3D-printed prototypes are created for functional validation. CAI/CAV inspection assures dimensional accuracy before final approval.

Documentation & Production Transfer

We deliver complete 3D CAD models, 2D drawings with GD&T, inspection reports, BOM, and supplier-ready packages for full-scale manufacturing.

Industries / Use Cases

Venttup’s reverse engineering services are trusted across these industries to deliver accuracy, compliance, and global standards – while promoting sustainability by reducing waste, emissions, and dependence on imports.

Energy

Recreate turbine and power equipment parts for reliable operations.

EV & Charging

Localize and optimize components for electric mobility systems.

Aerospace

Maintain and modernize high-precision aircraft components.

Defence

Replace obsolete or sensitive parts with secure local production.

Automotive

Develop and replicate vehicle components with high accuracy.

Medical Devices

Create prosthetics, implants, and healthcare components.

Electric Mobility

Rebuild large-scale spares for industrial equipment.

Shipbuilding

Manufacture and replace critical marine parts efficiently.

Typical Deliverables

Every project concludes with complete, production-ready documentation and verified outputs you can directly use.

Native CAD files (SolidWorks, CATIA, Creo, AutoCAD, Inventor).

2D drawing set with GD&T.

CAI/CAV inspection reports with comparison images.

Material certificates & PMI report.

Prototype and pilot production report.

Transform Your Product Design with Advanced Reverse Engineering Services in India

At Venttup Ventures, we redefine traditional manufacturing through our MaaS-based reverse engineering services in India. Instead of being a direct manufacturer, we operate as a manufacturing partner network, connecting industries with top-tier facilities, engineers, and advanced technologies to deliver accurate, scalable, and efficient reverse engineering solutions.

Our ISO-certified partners leverage 3D scanning, CAD modeling, and digital manufacturing tools to recreate, optimize, and enhance components across automotive, aerospace, and industrial sectors. Aligned with the China Plus One Strategy and Make in India initiative, we focus on sustainability, innovation, and speed-to-market — helping businesses modernize product development without heavy infrastructure investments.

Connect with Venttup

Request a Quote or Consultation

Frequently Asked Questions

If your question is not addressed here, please feel free to reach out to us. We value your inquiry.

What are reverse engineering services?

Reverse engineering is the process of recreating a part when no drawings or CAD files exist. Using tools like 3D scanning, PMI Analysis, Hardness testing and CAD software, generating accurate digital models and 2D drawings. These can then be used for part recreation, improvements, or large-scale manufacturing.

How long does reverse engineering take?

The time depends on the size and complexity of the part. Small parts may take only a few days, while larger or complex assemblies can take a few weeks because they require material testing, CAD modeling, and validation.

How much do reverse engineering services cost in India?

Costs vary based on the part’s size, geometry, and testing needs. Smaller parts are generally affordable, while complex assemblies require more effort. We recommend uploading your sample to get a free, no-obligation estimate.

Can you recreate an obsolete part without drawings?

Yes, absolutely. We can scan, measure and test the part to create accurate CAD files, 2D drawings, and even prototypes without drawings. This makes it possible to improve obsolete parts.

Do you sign NDAs and ensure IP security?

Yes. Every project is handled under a legally binding NDA, and we use secure transfer protocols to protect sensitive data, keeping intellectual property safe.

What file formats will I receive?

We deliver files in native CAD formats (SolidWorks, CATIA, Creo), as well as neutral formats like STEP and IGES. You’ll also get 2D PDFs, inspection reports, and supporting documents that are ready for production use.

Can you improve the design during reverse engineering?

Yes. Beyond recreating, we can also optimize it for better strength, durability, and manufacturability. This means you get a part that is accurate and performs better.