Have you ever looked at a product and wondered, “How did they make this — and can I recreate it?”

That’s exactly what reverse engineering services help you do.

Reverse engineering is the process of analyzing and reproducing an existing product, part, or system by studying its design, materials, and functionality.

In simple terms — it means rebuilding a physical object into a digital model (CAD) so you can redesign, improve, or manufacture it again — often using 3D scanning and CAD modeling tools.

What Is Reverse Engineering?

Reverse engineering is a technique used to understand, analyze, and recreate an existing object or component when its original design data (like drawings or CAD files) is missing.

Example:

Imagine you have an old machine part that broke, but you don’t have its drawing. Using 3D scanning, engineers capture every detail of that part, then convert it into a CAD model.

From there, they can redesign, repair, or reproduce it exactly.

What Are Reverse Engineering Services?

Reverse engineering services are professional solutions offered by engineering companies that handle this entire process for clients.

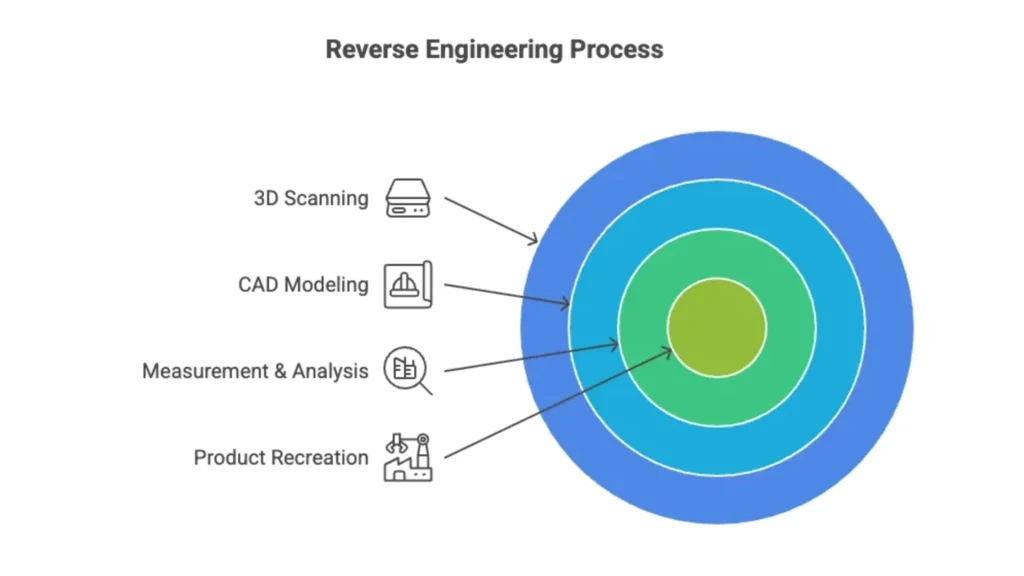

These services combine:

- 3D Scanning – capturing physical parts digitally.

- CAD Modeling – creating accurate digital 3D models.

- Measurement & Analysis – comparing scanned data with design standards.

- Product Recreation – manufacturing or redesigning parts based on the model.

Businesses use these services to recover lost designs, upgrade existing products, or analyze competitors’ products (ethically and legally).

The Step-by-Step Process of Reverse Engineering

The Step-by-Step Process of Reverse Engineering

| Step | Description |

|---|---|

| 1. Scanning | The physical object is scanned using 3D laser or structured light scanners. |

| 2. Data Processing | The captured data (point cloud) is cleaned and converted into a mesh. |

| 3. CAD Modeling | Engineers create an accurate 3D CAD model using the mesh data. |

| 4. Validation | The new model is compared against the original part for precision. |

| 5. Reproduction or Redesign | The final CAD file is used to recreate or improve the part. |

Quick Tip:

Always verify scanning accuracy before creating CAD models. Even small errors in data can lead to fit or function issues later.

Applications of Reverse Engineering

Reverse engineering services are widely used across multiple industries in India and worldwide:

- Automotive: Recreating legacy parts or discontinued components.

- Aerospace: Ensuring precision replacement of high-value parts.

- Manufacturing: Digitizing old molds, tools, or machinery.

- Medical Devices: Analyzing complex implants or devices.

- Consumer Products: Studying competitors’ designs for improvement.

Benefits of Reverse Engineering

- Rebuild old or damaged components without original drawings.

- Reduce design time and cost in R&D.

- Improve performance or efficiency of existing products.

- Support quality checks through digital comparison.

- Extend the lifespan of industrial equipment.

Pro Tip:

Reverse engineering isn’t just about copying. It’s about learning, improving, and modernizing existing products to meet new design or production goals.

Why Reverse Engineering Matters in 2026

With India’s growing manufacturing and product design sectors, the demand for 3D scanning and CAD-based reverse engineering has skyrocketed.

- Global 3D scanning market projected to exceed USD 8 billion by 2026.

- Indian engineering firms increasingly use reverse engineering to modernize legacy infrastructure and develop local manufacturing capabilities.

These services bridge the gap between old designs and modern innovation, allowing Indian companies to stay competitive.

Conclusion

Reverse engineering services make it possible to recreate, improve, and modernize products that once seemed impossible to reproduce.

Venttup provides professional reverse engineering services in India, helping businesses accurately recreate, analyze, and improve existing parts through advanced 3D scanning and CAD modeling solutions.

Frequently Asked Questions

What is the main purpose of reverse engineering?

It helps analyze, reproduce, or improve an existing part or product when design data isn’t available.

Is reverse engineering legal?

Yes — it’s legal when used for repair, analysis, or innovation, but not for copying patented designs.

How much do reverse engineering services cost in India?

Prices vary based on complexity — typically ₹5,000 to ₹50,000+ per part, depending on scanning and modeling needs.

What tools are used in reverse engineering?

Professionals use 3D scanners, CMM machines, CAD software (like SolidWorks, CATIA, NX), and specialized analysis tools.

How long does the reverse engineering process take?

A single part may take 1–7 days depending on its geometry, scanning detail, and modeling depth.

Can reverse engineering improve old designs?

Yes. Engineers can analyze old parts and make performance or durability improvements using CAD redesign.

Which industries benefit most from reverse engineering?

Automotive, aerospace, manufacturing, energy, and healthcare industries use it widely for maintenance and innovation.

Why choose a professional service like Venttup?

Venttup provides end-to-end reverse engineering with accurate 3D scanning, CAD expertise, and quality assurance — trusted across India for engineering precision.