In 2024, the global CNC market size had reached $90.5 billion. According to the IMARC Group, this statistic is expected to grow up to $144.4 billion by 2033 with a CAGR of 5.06%.

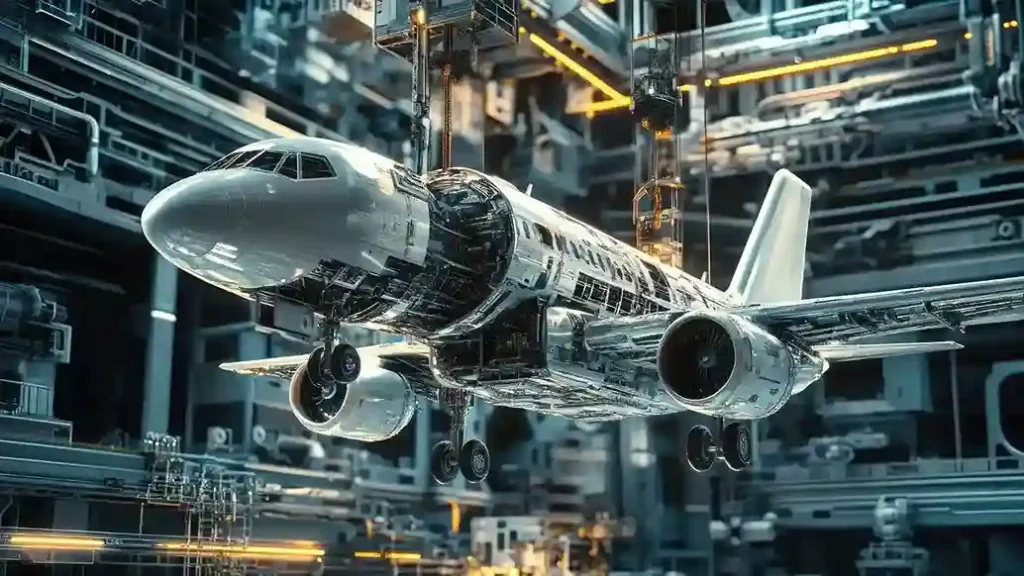

CNC machining is the new answer to modern manufacturing needs. It is a computer-based manufacturing process that meets the precision to micron levels required in aerospace engineering, marine and space research.

But how does CNC machining work, and what might be going on inside a CNC machining process? Here, we’re going to explore everything related to CNC machining. Whether you’re an engineer, product designer, procurement professional, or curious learner, this blog is designed to answer the questions you have in your mind. Enjoy reading.

What Is CNC Machining?

CNC machining is a digital manufacturing process in which computer software guides the movement, speed, and actions of machines like lathes, mills, routers, and grinders. Unlike traditional machining, where we have to manually do everything, CNC machining relies on G-code, a special language that instructs the machines. It offers fast manufacturing.

Example: Imagine you need a hundred metal car parts. Here, you can use CNC machines to create every part with a tight tolerance instead of your workers cutting each one by hand.

How CNC Machining Works: Step-by-Step

CNC machining turns digital designs into real-world parts with high accuracy and consistency. Let’s explore how CNC machining works in 6 simple steps:

1. Design the Part (CAD)

The CNC machining process begins with a digital blueprint of the equipment. The engineers create 2D or 3D designs of the part using CAD (Computer-Aided Design) software like AutoCAD and SolidWorks. This model includes all the exact measurements, shapes, and tolerances needed.

2. Convert CAD to CAM (Programming the Job)

Once the design is complete, it’s uploaded into CAM (computer-aided manufacturing) software such as Fusion 360 or Mastercam. This is when the machining strategy is created. The planning covers deciding which tools to use, how they should move, and in what sequence.

The CAM system then generates the set of instructions (G-code) that tells the CNC machine how to produce the part.

3. Machine Setup and Preparation

In the next step, the technician prepares the physical setup for CNC machining.

- Choosing the right machine (lathe, mill, or router)

- Securing the raw material (metal, plastic) in place

- Loading and calibrating the cutting tools according to the program

4. CNC Machine Operation Begins

This is where the real CNC machining begins. The machine reads the G-code uploaded to it and follows every instruction one by one with perfection.

- Drilling: Creates precise holes at exact locations

- Milling: Remove layers of material to shape surfaces or contours

- Turning: Rotates the material to form round or cylindrical parts

- Cutting: Trims or shapes the workpiece to match the desired profile

5. Real-Time Monitoring and Adjustments

CNC machines have built-in sensors and software monitors to watch over the precision, speed, tool wear, and material resistance of the machines while they work. The machine automatically adjusts itself to avoid any defects in manufacturing if it malfunctions.

6. Finishing Touches and Inspection

After machining, the part may go through finishing processes such as

- Deburring sharp edges

- Surface polishing or coating

- Washing off any debris

Each component goes through several quality checks using inspection tools to make sure it matches the CAD design.

Why CNC Machining Matters

CNC machining is the go-to option for manufacturing critical components of various industries that run the world. Do you know why they’re trusted across the globe?

- Accuracy:

Precision is crucial for medical, aerospace, and automotive components. Here, CNC delivers tolerance as tight as ±0.001 inches (finer than a human hair).

- Fast Track Solution:

Manual machining is like writing a notebook, and CNC is like printing it. This process can save days and provide faster delivery without compromising quality.

- Uniformity:

CNC machining never leaves space for mismatched pieces. The first one will look exactly like the last with zero variations.

- Economic Sustainability:

CNC machining cuts metal and plastic. They also cut your unnecessary costs by minimizing product waste, rejected parts, and the need for rework.

Types of CNC Machines

There are various types of CNC machines, and they are used to create different CNC models. Understanding them will help you learn how CNC machining works.

| Machine Type | How It Works | Best For | Typical Applications |

| CNC Milling Machine | Uses rotating cutters to remove material from a stationary workpiece | Flat or contoured surfaces | Engine blocks, metal housings, molds |

| CNC Lathe | Spins the material while a fixed cutting tool removes material | Cylindrical or round parts | Shafts, bushings, pipe fittings |

| CNC Router | High-speed machine for cutting softer materials like wood or plastic | Large, flat sheets and soft materials | Signage, cabinet panels, acrylic displays |

| CNC Plasma Cutter | Uses a plasma torch to cut through metal sheets with high temperature and speed | Fast metal cutting | Automotive panels, industrial metal sheets, signage |

| CNC EDM | Uses electrical sparks to shape hard metals without physical contact | Extremely hard or intricate parts | Dies, molds, hardened tool components |

Real-World Example: CNC in Action

Are you ready to understand the whole process involved in creating a critical component? We’re going to take an example of an aerospace manufacturer that needs to produce 100 precision aluminum brackets.

- Engineers begin by designing the bracket using CAD software.

- The programmer uploads the design into the CAM software.

- The software calculates the toolpaths for a 5-axis CNC milling machine.

- The machinist loads aerospace-grade aluminum blocks into the machine.

- The component will be ready in the next 45 minutes with the desired quality and measurement.

- CMM (Coordinate Measuring Machine) checks every bracket for dimensional accuracy.

Ultimately, you receive 100 identical, high-precision parts produced efficiently with minimal waste.

Advantages of CNC Machining

Want to know how CNC machining benefits the specific sector you work in? Let’s take a deeper look at it.

- Tight tolerances for aerospace:

Delivers ±0.001 accuracy for flight-critical parts and structural components.

- Consistent output for automotive suppliers:

Makes sure every gear, bracket, or housing is identical in every batch.

- Fast turnaround for product developers:

You can move from the CAD file to the working prototypes in a day.

- Efficient scaling for precision manufacturers:

Seamlessly handles both short-run and high-volume jobs without retooling

- Low labor demand for contract shops:

One operator can run multiple machines, reducing costs without sacrificing quality.

- High complexity for medical device makers:

Easily produces small, detailed, multi-surface parts from titanium or stainless steel

- Material savings for high-cost alloys:

Precision cutting minimizes scrap and lowers per-part cost on expensive materials.

Why Understanding How CNC Machining Works Matters

Why should I learn how CNC machining works if I’m not a machinist? Let’s answer the question for you.

- Are you a student in engineering or design?

You get better internship opportunities and career chances by showing your recruiter that you possess in-depth knowledge of the practical aspects of CNC machining. - Are you a buyer or procurement lead?

You can avoid mistakes and the cost disadvantages by asking the right questions and making better sourcing decisions. - Are you building a product or a startup owner?

Knowing how CNC works lets you design parts that are easy to produce, affordable to test, and fast to revise.

Key Points Covered

- Industries depend on CNC machining to produce high-precision parts.

- CNC machining helps in manufacturing superior-quality components at cost-friendly prices.

- Learning how CNC machining works will be an asset to your career and business growth since it can impact how you make major decisions.

Conclusion

CNC machining is the modern solution for complex manufacturing requirements. Because of this, CNC machining has created an increasing demand for CNC-machined products, machinists, and programmers.

When you understand how CNC machining works, you can improve your knowledge base in the manufacturing industry to make better business decisions and create smarter components. The blog has provided useful insights to the engineering students as well.

Are you searching for cost-effective CNC manufacturing in India?

Venttup Ventures is one of the best CNC machining services in India that supplies export-quality CNC products all around the world. We help global industries access affordable CNC-machined solutions with better logistics and supply chain management.

Worried about the growing global conflicts affecting your company? Connect with us today for the high-tolerance components manufactured in India.